Filter cartridges have, in some customer’s views, been deemed an inferior solution but the main reasons for this are generally due to suppliers specifying the wrong media, pleat format and pleat depth for the application due to the limitations of their own product portfolio.

The fact is, most dust control equipment manufacturers only have one or two options in their range making some units unfit for specific purposes. Dustcheck however are experts in cartridge filter selection and can supply a huge range to suit individual applications; having the unique advantage of being able to offer different pleat formats and pleat depths as well as the filter media itself.

This enables us to select the correct format for the application and gives us the ability to confidently provide an optimum solution where others may have to risk a compromised offering due to their limited range or even resort to the application of larger, more expensive bag filters.

Pleat Depth

Aside from selecting the right filter media for an application, one of the most vital considerations when selecting filter elements is to ensure that you use the correct cartridge format for the type of dusts being handled.

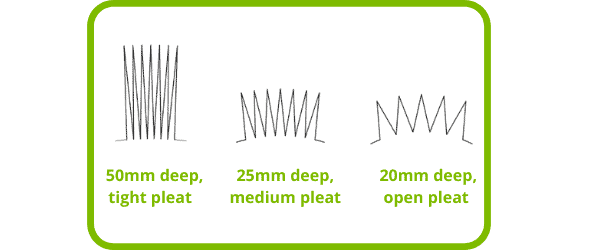

The correct application of pleat depth and spacing of a cartridge will depend on the characteristics of the material you are filtering. If the particulate is fine and free flowing the 50mm deep tight pleated elements are usually adequate and these cartridge formats are the standard offering by most filter unit manufacturers.

Even in this format however, the elements provided in Dustcheck filter units have superior performance due to ridges being made in the media during the manufacturing process which keep the pleats apart and minimises ‘closing’ under dust load which other manufacturers elements can be prone to.

This occurs when dust enters the ‘valley’ between the pleats and air pressure pulls the pleats together, sandwiching and trapping the dust and hindering efficient cleaning. Our pleat distance control measures enable Dustcheck units to maintain less differential pressure and more consistent air flow; prolonging cartridge life and saving energy.

With difficult applications where particulates are more challenging i.e., fibrous or less free flowing, deep pleated elements may not be deemed to be the correct solution and in this instance most filter unit manufacturers would either not be able to provide a solution at all or may be forced into a larger, higher cost bag filter solution if it is available to them.

As Dustcheck can provide cartridges with alternative pleat depths and spacing such as the 25mm and 20mm pleat options, it enables us to tailor the filter to the requirements of the application while still maintaining the benefits of a more compact, cost-effective solution.

Significant advantages

Cartridge filters give significant advantages over bag filters:

- They’re more compact so great for keeping your filter footprint as small as possible i.e., significant space-saving compared to bag filters for the same duty

- They have a higher efficiency than equivalent bag media

- They save time on maintenance as cartridges are easier to replace which reduces maintenance cost and valuable production downtime

Correctly applied, cartridges will out-perform bags in efficiency and filter-life in most cases. Plus, just like with bags, cartridges can be successfully laundered if required as long as correct instructions are followed.

The only limitations with cartridge filters is the temperature at which they can operate; circa 130oC. Bag filter technology can significantly exceed this however in some instances it is possible to utilise additional dilution air to reduce process temperature to within the limits of a cartridge filter and still be more compact and cost effective than a bag filter.

Filter bags usually have a lower replacement cost than cartridges per element due to the differences in construction, but when considering the increased filter area and therefore reduced number of elements per unit along with minimised maintenance requirements and production down-time the ‘whole of life costs’ of cartridge filters can be significantly lower.

Our cartridges are primarily offered in conical format which offer clear advantages in comparison to parallel designs. The conical shape improves the performance of a system in numerous ways:

- Improved dust release

- Reduced dust re-entrainment

- Uniform cleaning over the length of the element

- Enhanced pre-separation lowers the dust load onto elements

- Improved cleaning action extends the life of the cartridges