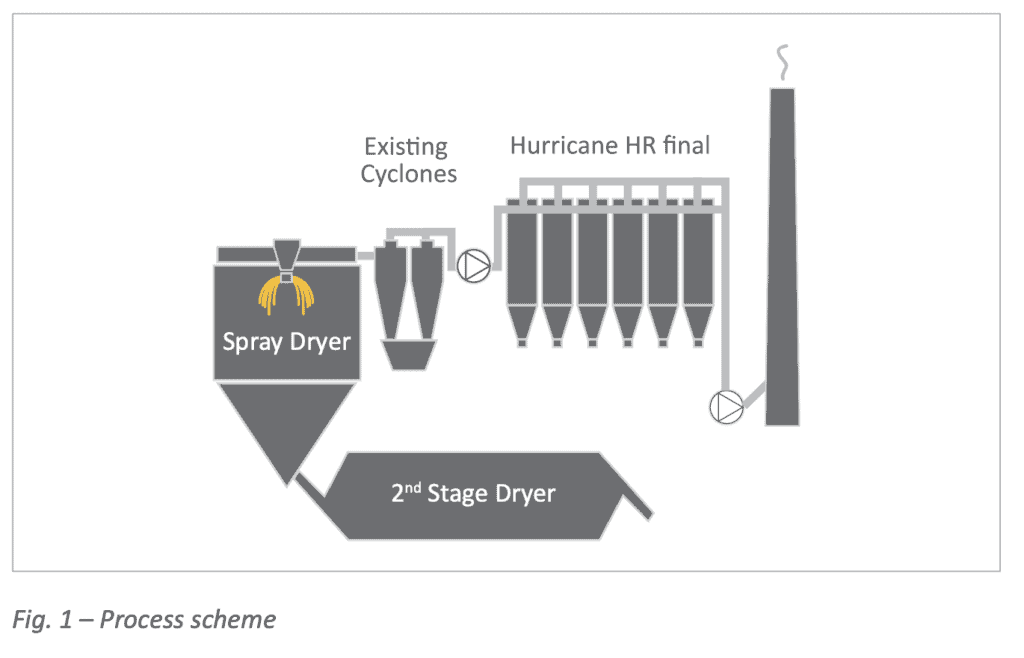

ACS’s system was installed in the production plant of Azores, on the beautiful island of S. Miguel. ACS was contacted with the objective of reducing particulate matter (PM) emissions under 75mg/Nm3 from a Drying Tower of Powder Milk (Fig. 1). The existing cyclones installed after the Spray Dryer at Néstle’s plant had emissions of around 170mg/Nm3, besides being above the emissions limits this valuable product was being lost to the atmosphere. Total annual losses reached 320 tons of caseinate per year, estimated in several millions of Euros.

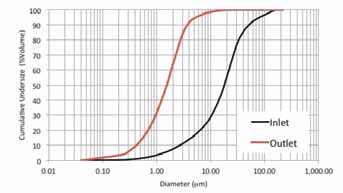

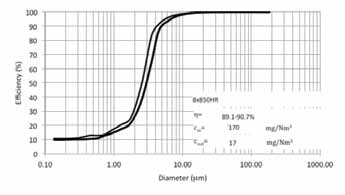

In order to design the most efficient system for this case, an isokinetic dust sample was collected at the stack and measured by ACS in a laser sizer to Obtain the Particle Size Distribution (PSD). After stack tests confirmed the PSD (Fig.3), ACS designed a Hurricane system comprising 8 Hurricane HR numerically optimized cyclones with ø850 mm, disposed of in 2 batteries, operating in parallel. The system is capable of guaranteeing emissions under 75mg/Nm3 (expected under 50 mg/Nm3) at a pressure drop of 1.7 kPa.

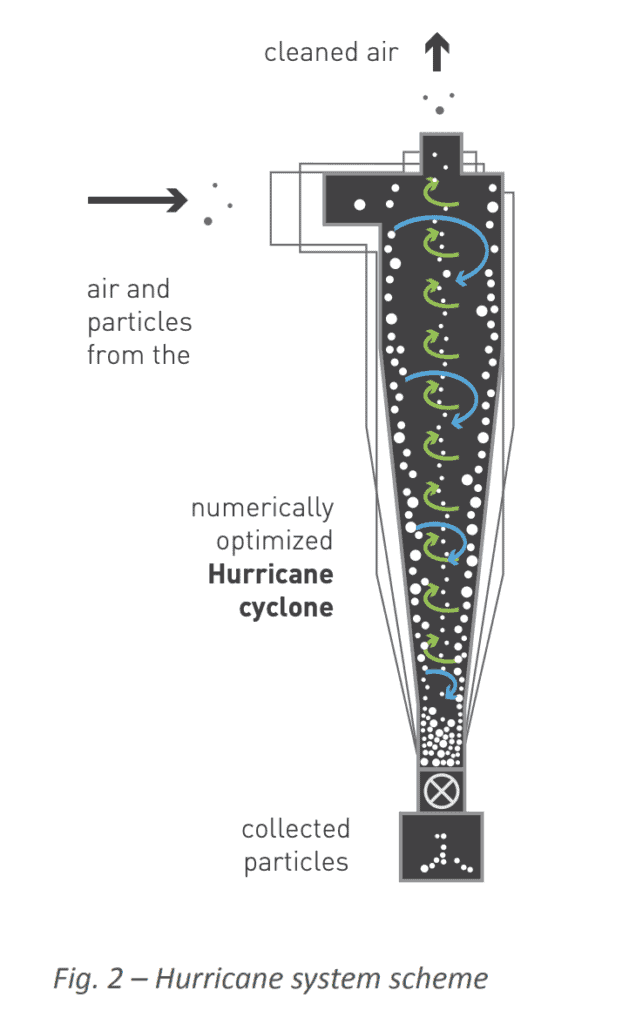

Understanding How Cyclones Work

The separation dynamics inside a cyclone is very difficult to model. Cyclones are usually designed empirically or, less often, according to models which do not consider the interparticle agglomeration inside the cyclone. ACS has developed its own unique model for cyclone efficiency prediction which takes into account agglomeration in turbulent flow fields – The PACYC MODEL (Chemical Engineering Journal 162 (2010) 861–876.

Optimizing Cyclone Efficiency

Supported by the PACyc Model, ACS can rapidly generate millions of virtual prototypes (cyclone geometries) and, through numerical optimization, select the best geometry for each given case. The design takes into consideration several economical and operational constraints, such as size, pressure loss or manufacturing cost. ACS Hurricane HR cyclones have been demonstrated to be more efficient than any other known cyclone available in the marketplace for the same pressure drop and manufacturing cost. ACS’ competitive advantage is sustained by a unique ability to accurately estimate – and consequently guarantee – a requested efficiency, resulting in better cyclones, tuned for their specific application.

About hurricane cyclones

Design Basis

- Powder [Milk powder]

- Particle size distribution [Fig. 3]

- Gas flow temperature (ºC) [70-80]

- Effective flow rate (Nm3/h) [31 100]

- Normalized flow rate (Nm3/hdry ) [21 150]

- Inlet concentration (mg/Nm3) [245]

System Specifications

- Guaranteed maximum emissions (mg/Nm3) [75]

- Expected maximum emissions (mg/Nm3) [<50]

- Expected total pressure drop (kPa) [1.7]

Conclusions

Results confirm the Hurricane Cyclone System, achieving PM emissions under 50 mg/Nm3, thus assuring the achievement of future imposed emission standards with equipment that has lower investment costs, BFs, and lower maintenance and operating costs, when compared to Bag Filters.