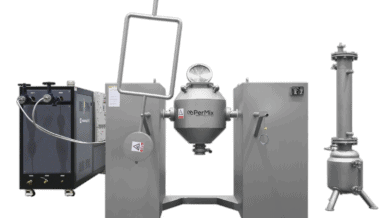

MIX range of mixing machineries includes mixers, reactors, dryers, humidifiers, heaters, coolers, sterilizers, granulators, stirred bunkers. Processes can be executed in batch or in continuous. Always attentive to the needs of its Customers, MIX developed a new range of Reactors and Dryers suitable for specific challenging processes. With MIX machineries, customers are now able to manage pressure and temperature variations, dangerous and toxic dry raw materials with vacuum process, even in ATEX classified environment.

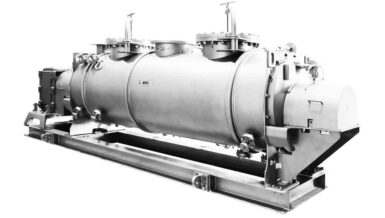

Recently MIX delivered to an European leading Chemical group, a system of machineries with the aim of batch vacuum drying a crystalline salt. Raw material is toxic, explosive, difficult to treat, and clogging. At the beginning of the process, the crystalline salt has a variable content> 5% of methyl alcohol. The purpose of the process is to reduce the content of methyl alcohol to a value <0.1%. The system of machineries supplied by MIX includes one mixer / stirred bunker with ribbon shaped tools and one mixer / reactor with paddle shaped mixing tools. The ribbon stirred bunker continuously receives the raw material from a previous treatment and, like a buffer IBC, feeds the mixer / reactor whenever it is required by the system logic of operation.

Raw material enters into the dryer at -5°C, at atmospheri pressure; the drying process is executed at a pressure of +70 mbar absolute, at a temperature of about +20°C as the material is perishable above +30°C. The reactor / dryer is equipped with heat exchanger for hot water, both on the vessel and on the rotor shaft for a better performance and has an ATEX certification II 2G suitable for use in zone 1, for both external and internal parts. The inerting of the mixing / drying chamber is guaranteed by the introduction of CO2 through the flushing of the rotor shaft seals. The provided automation system is able to analyze constantly the variations of temperature and of vacuum level inside the mixer / dryer. The system is able to compare actual levels of temperature and pressure with process target levels and consequently manages to calculate the time needed to complete the process.

In this way it is the system itself that autonomously determines the most appropriate moment to discharge the dried product and to start a new batch. The entire process lasts approximately 60 minutes, including filling and emptying of the mixer / dryer. The mixer / dryer is equipped with a special self-cleaning de-dusting filter, equipped with heating system and insulation to prevent condensation. The filtering elements, in stainless steel, are suitable for continuous use even in the presence of acid products.

In its mission, MIX operates not merely as a supplier, but as a reliable partner being able to develop new solutions and increase the efficiency of the production processes. Every mixer is tailored and custom manufactured, in order to satisfy even the most demanding and specific requirements. Each mixer is designed to be able to optimally perform the productive tasks, for which it has been conceived.

Thanks to the advanced internal test laboratory, it is always possible for MIX and for its Customers to securely test new recipes and to reproduce even the most complicated industrial production processes.

In this way, it becomes much easier to determine the characteristics of each raw material and, therefore, identify the most suitable mixing techniques for obtaining the desired result. Since several years, MIX s.r.l. has been investing in quality system through new certifications on industrial management system. Therefore, the company has been working on all levels to obtain the certification to ISO international standards of QUALITY (ISO 9001), ENVIRONMENT (ISO 14001) and SAFETY (ISO 45001).