“We’re a food ingredient manufacturer specialising in dough conditioners, bakery concentrates, premixes, and toll dry blending,” says CEO Brad Keating. “We do liquid processing and repackage liquid sweeteners, as well.”

Adding manufacturing to distribution

Originally a distributor, KB Ingredients also became a manufacturer in 2015, offering customised ingredient blends, pre-mixed dough conditioners, and toll blending.

To house the new manufacturing line, the company erected a mixing production room with a 8.5 m ceiling at its New Jersey facility.

For the new space, it purchased three ribbon blenders to mix combinations of dry ingredients, including flours, sugars and fine granular products, as well as a packaging line to fill, heat-seal and palletise 23 kg bags or cartons.

Staging and storing of blended material in bulk bags prevents bottleneck

Since the combined output of the ribbon blenders exceeded that of the packaging system, KB Ingredients decided to store blended material in bulk bags for subsequent packaging. Each blender now discharges mixed product into palletised bulk bags which weigh 454 to 1136 kg depending on material density, for storage and subsequent packaging.

When needed, the bulk bags are unloaded using a Bulk-Out® BFF bulk bag discharger supplied by Flexicon Corp. An operator slides the bag’s four lifting straps into Z-Clip™ strap holders on the bag lifting frame, which is raised by forklift and placed into top-mounted receiving cups atop the frame’s four posts.

The operator then connects the bag spout to a Spout-Lock™ clamp ring which creates a sealed connection between the clean side of the spout and the clean side of a Tele-Tube™ telescoping tube, protecting the integrity of the blended mixture. As the tube then lowers, it keeps the spout taut, promoting flow and total evacuation while preventing dust. The discharger also includes Pop-Top™ upper frame extension arms that raise and elongate the bag as it empties to further promote complete discharge.

The blended material flows from the bulk bag into a 227 l floor hopper designed for powdery, semi-free flowing materials. A pneumatic turbine vibrator on the hopper aids flow. The hopper feeds a 4.6 m long, 114 mm O.D. flexible screw conveyor inclined at 45º, which transfers material to a 305 mm diameter circular separator mounted above another hopper, from which the product gravity feeds to the packaging machine below.

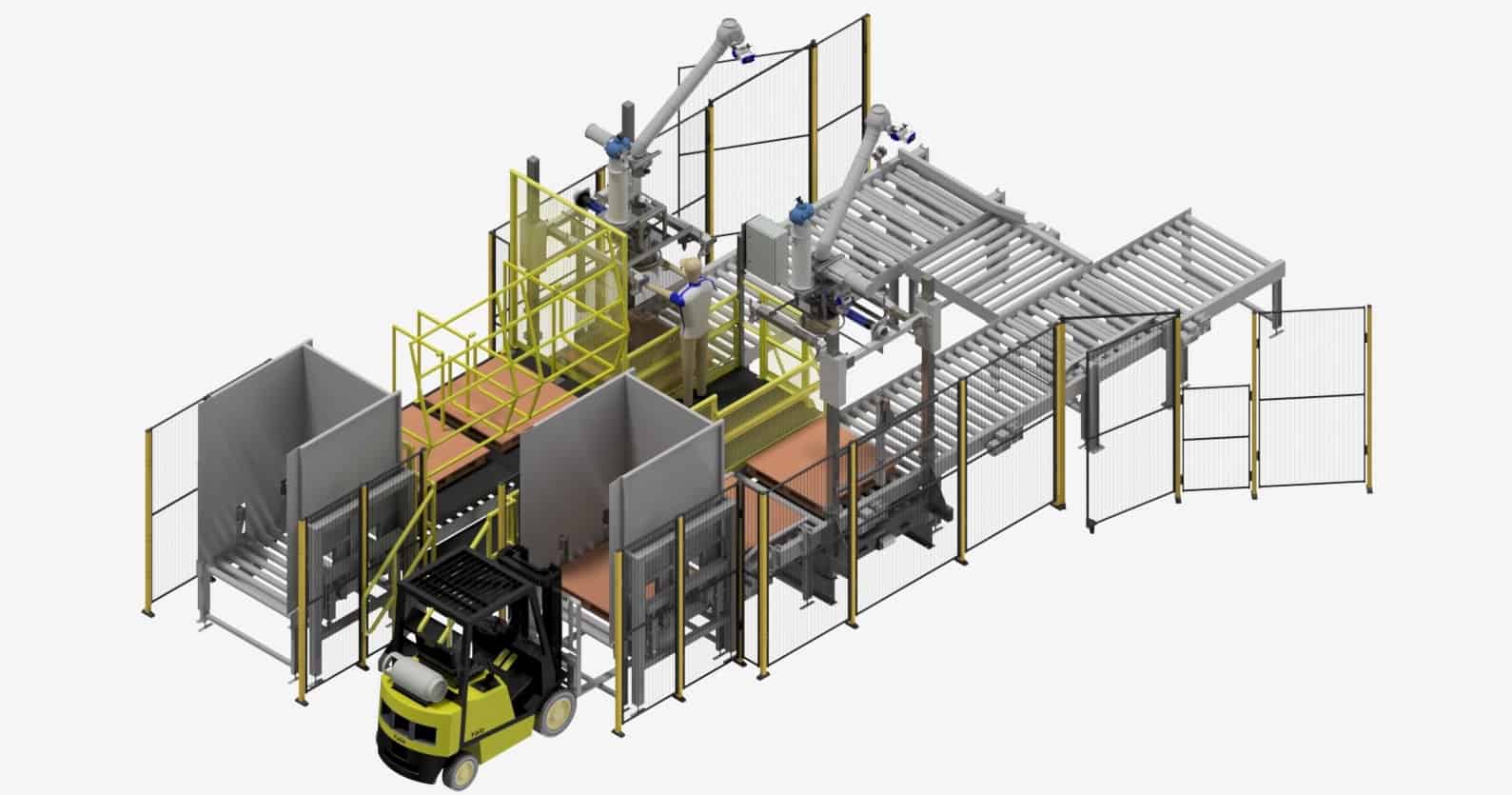

Second bulk bag discharger system expands capacity

To provide redundancy, the company added a second model BFF bulk bag discharger in 2017. “At the time, we didn’t need the capacity,” says Mr. Keating, “but now our volume is picking up to where we’re utilising them both.”

The second system incorporates the bulk bag discharger, a 610 mm diameter vibratory screener and a packaging machine, all stacked in a 5.2 m high discharger frame. The high ceiling in the process room allows this arrangement, Mr. Keating points out, minimising footprint. A bulk bag is loaded into the discharger by forklift as with the original discharger, except the operator climbs a step ladder to access the higher bag spout connection.

To control flow to the sifter, the bag spout interface is fitted with a Power-Cincher™ flow control valve containing four elliptically shaped cincher bars that converge and overlap to allow partial or complete closure of the bulk bag spout. The discharger also incorporates Flow-Flexer™bag activators that raise and lower opposite bottom edges of the bag to promote material flow and total evacuation.

Maintaining and cleaning the bulk bag systems

“The systems are essentially maintenance-free with few moving parts,” says Mr. Keating. “The only thing on the flexible screw conveyor that you have to maintain is the 2.2 kw motor.”

“We are cautious about cross-contamination because allergens are present,” Mr. Keating says. Cleaning takes two to three hours, including the hoppers, flexible screw conveyor, screeners and packaging machine. KB Ingredients uses the original discharging system with flexible screw conveyor for longer production runs where changeover time has less impact, and the newer discharging system for shorter runs.