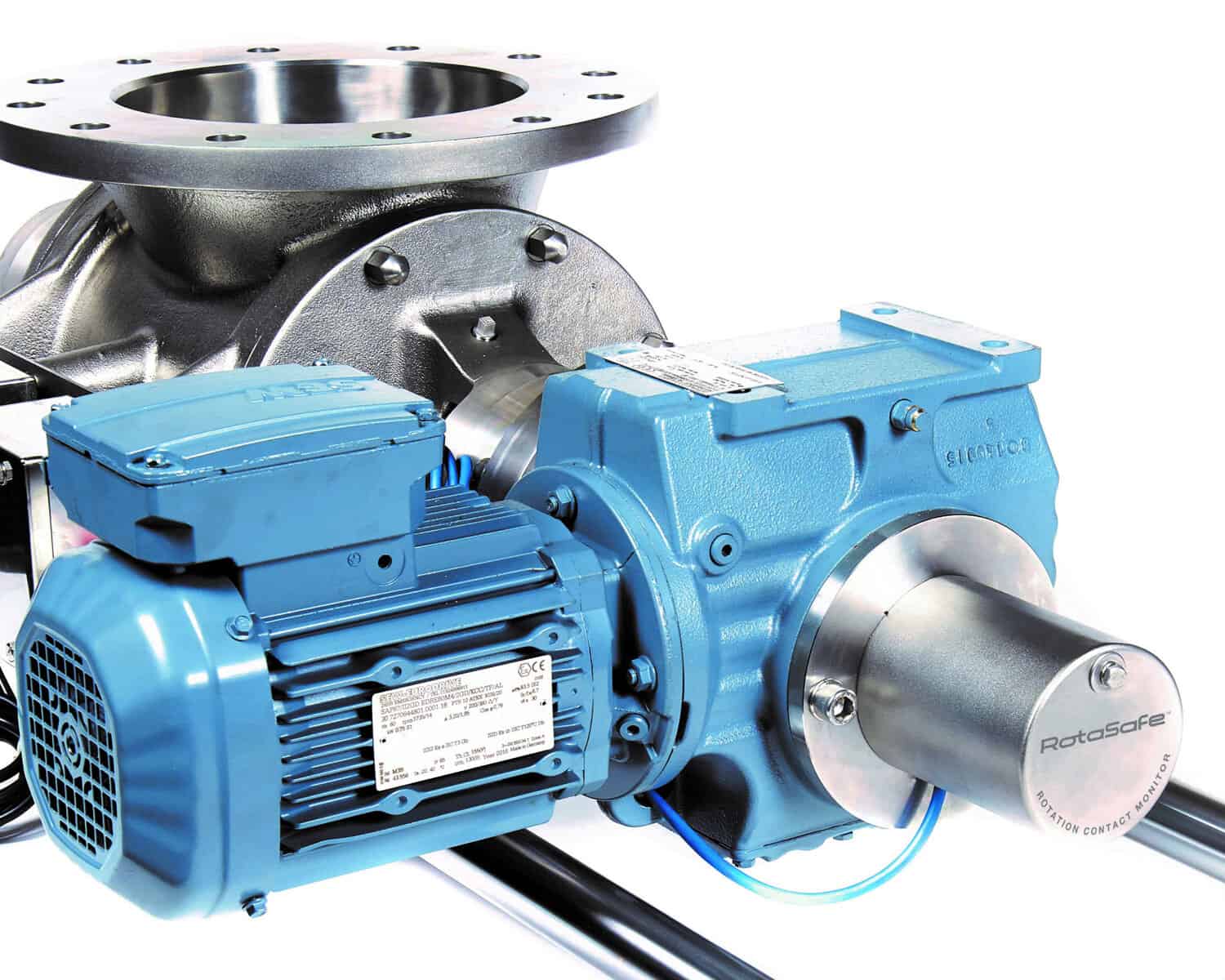

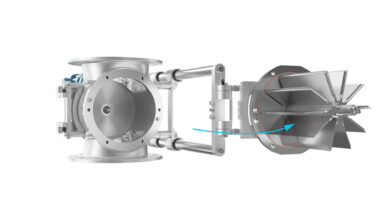

A rotary valve is simply a mechanical device used for the continuous discharge of bulk solid materials. The term ‘rotary’ is derived from the valve’s operating principle. During bulk material handling, the valve’s vanes rotate to produce a successful operation, hence, the term ‘rotary’. The valve is an essential component in the bulk handling industry. Its main functions are to (i) regulate bulk material flow in the system and (ii) prevent air leakages, hence, maintaining constant air pressure in the system. The rotary valve has two ports, the inlet port which serves as the bulk material entry point and the outlet port which serves as the bulk material exit point. During operation, the bulk material goes in via the valve’s inlet and is transported across the valve’s housing surface to the outlet by means of the rotor pockets as the rotor shaft rotates. There are two types of rotations namely, the load side rotation and the return side rotation. The former is considered to be the rotation of the vanes and the pockets from the entry point to the exit point, while the latter is the rotation of the vanes and the pockets from the outlet to the inlet. Regardless of the valve’s simple construction, it is adjustable to meet most industrial applications. An incorrectly used valve can lead to inadequate efficiency, equipment wear, accelerated product degradation, production loss because of process shutdowns etc.

Polimak offers an excellent variety of rotary valves to assist our customers with the efficient handling of bulk solid materials. We aim at designing and manufacture state-of-the-art rotary valves targeted at providing quality performance during bulk material handling. We provide valves that operate in industries such as food, chemical, agriculture, foundry, mining and aggregate and many others. Some of the bulk materials which are handled by our valves include cement, calcite, ash, glass powder, marble powder, plastic pellets, sawdust, fly ash, coal, coal dust, wheat, flour, barley, feed, seed, corn, chickpea, bean, soybean, sesame, rice, rice flour, dried fruit, nuts, peanut, almond, sunflower seed, cottonseed, grain cereals, chestnut, coffee grain, coffee powder, sugar, salt, spice etc.

In the aforementioned industries, a rotary valve is used in many different applications. The valve is assembled with other bulk solids handling equipment to attain a particular purpose. Our rotary valves can be utilised as follows in industries.

- Empyting of silos.

- Emptying of cyclones.

- Dust collection systems.

- Batching, mixing, and dosing systems.

- Pneumatic conveying systems.

- Conveyor feeding or discharging.

- Screw feeder feeding and discharging.

- Filling and emptying of bulk solids.

- Feeding and discharging of bulk solid processing equipment.

Polimak provides various rotary valve configurations designed to provide solutions to a wide range of industrial processes. With over four decades of industrial experience, we are always ready to provide solutions for your bulk handling by helping you select the right design and configuration to meet your specific application requirements.