Achieving higher throughput while maintaining high quality requires continuous monitoring of the production process, which can also help eliminate lost batches and save a significant amount of otherwise wasted time and materials.

Eliminate bad batches

Bad batches can be the result of non-homogeneous mixes or defective load cells. These create a major financial risk when the batching process is extended for days or even weeks due to rework.

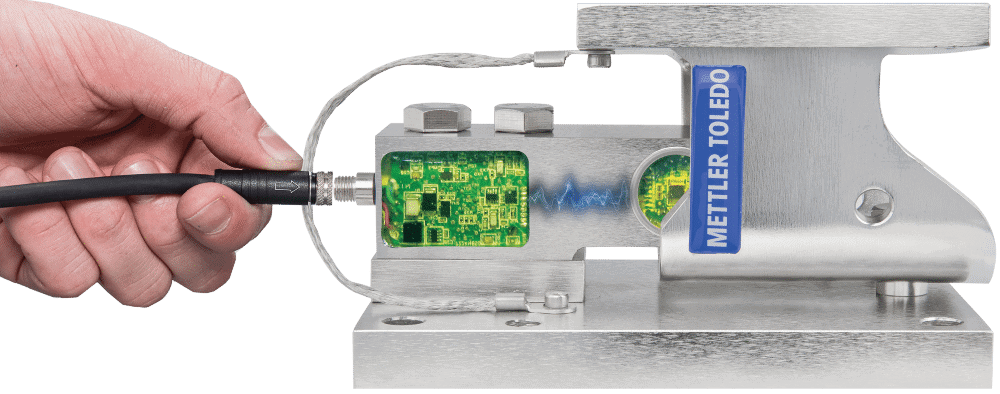

The new POWERCELL® load cells from METTLER TOLEDO help to avoid bad batches by providing control over the content of your tanks and the material distribution within. These smart load cells feature integrated microprocessors that perform continuous condition monitoring and provide predictive maintenance information. This means the load cells can also detect non-homogenous ingredient accumulation on one side of the batching tank. This real-time feedback gives you the ability to take corrective action before the expensive batch loss occurs.

Monitor even if a load cell fails

In the unlikely event of a load cell failure, POWERCELL® enables the completion of the batch. This is because TraxEMT™ on-board predictive maintenance technology allows the IND780 weighing terminal to continuously monitor each load cell. The “run flat” function uses the other load cells and historical load distribution data to compensate for the faulty unit until it can be replaced.

Prepare for future automation

Besides helping process engineers to achieve higher yields, METTLER TOLEDO’s POWERCELL® load cell technology enables the collection of detailed measurement and diagnostics data. This creates a new and improved approach to process control and optimization, which is a prerequisite for any future transition to fully automated production.

Reduced downtime, faster troubleshooting, and fewer bad and lost batches: POWERCELL® load cells inside PowerMount™ weigh modules pave the way for overall improvements in quality, compliance, and productivity.