In line with the available investment budget volume Daxner planned, delivered and installed a complete gravimetric mixing line equipped with components in hygienic design. The system provides high throughput performance, total flexibility for product changeovers and easy cleaning design. Another essential objective was to ensure utmost mixing accuracy and to enable a gentle and hygienic addition of micro-ingredients. This was achieved by reducing cross contaminations in order to maintain product quality. The minimization of cleaning times and a design for minimum overall operational costs were decisive design criteria.

Blending

All micro and minor components are solely pre-commissioned in the corresponding allergen rooms. These rooms are physically separated from each other in terms of the handled allergen and therefore they only permit access with hygienic, protective clothing. Subsequently, a forklift truck positions the bags and the pre-commissioned ingredients onto the operating platform. There, the operator fills the ingredients into one of the two existing VIB & PRESS bag intake stations (=combined intake station, control screening machine & de-agglomeration device!).

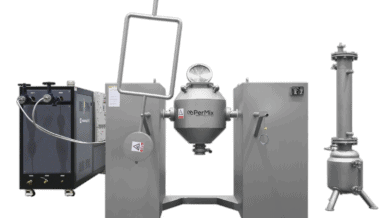

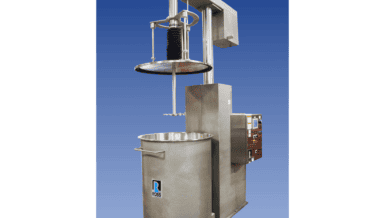

Depending on the product characteristics the mixing system itself is specifically selected. Line 1 is equipped with a horizontal paddle mixer and line 2 with a horizontal ploughshare mixer (both optionally equipped with cutting rotors or chopper knives), in order to provide highest flexibility for various mixing jobs.

The mixers are designed according to the latest sanitary standards! Two large cleaning doors provide easy cleaning access to the mixing chamber. The mixing system enables a high mixing accuracy (higher than 1:100.000) and short mixing times ranging from 1 to 5 minutes. Also, ingredients with different bulk characteristics (bulk density, particle sizes, and structure) can be added to the mixing process.

The DAX-PVS bag filling and the weighing system fills the finished ingredient mixes into 15-20 kg packages and is located below the mixer receiver bin. This completely gravimetric and compact designed bag filling station combines simple, semi-automatic handling with high throughput and easy cleaning (no residue!).