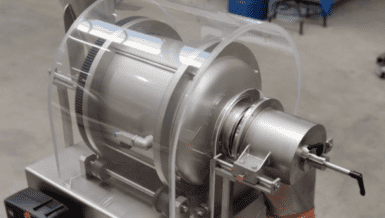

The JEL RRM drum hoop mixer is used for the mixing, homogenization, and coloring of a variety of bulk solids and fluids. Available with a mixing container capacity of 50-400l, the gravity mixer covers a broad spectrum of tasks. To meet the growing demand for high-value and hygienic mixing solutions, Engelsmann is now offering the JEL RRM in a new hygienic version that has been specially developed for use in hygiene-conscious sectors such as the pharmacological and food industries.

Here, along with making the mixer easy to clean, our top priorities were the avoidance of dead spaces and stopping product residues from accumulating. Therefore, all of the hygienic version’s surfaces are especially flat and all internal parts are very easily accessible. As the drum hoop mixer can be completely dismantled, it can also simply be disassembled into its individual components, so that the user can clean and disinfect them thoroughly. In the focus of the reworking of the model was the roller track on which the drum hoop is positioned with its drum mounting and mixing container.

Instead of construction made up of several parts, the new hygienic variation consists of a single component made of welded stainless steel. Thanks to the open design and flat surfaces, it can be cleaned quickly and easily. The roller track is reinforced with cross tubes that, due to their round shape, do not offer any space for product residues or dirt. The drum hoop mixer is driven by an aseptic motor that is perfectly suited for use in hygiene-sensitive industries due to its smooth casing. The drum mounting is covered with a special anti-sliding coating that meets FDA requirements to hold the mixing container securely while the machine is in operation. The cladding is equipped with star knobs made of stainless steel for simple dismantling.

The optionally available three-wing mixing insert that can be used to optimize mixing intensity in the barrel was also put on the test bench: The body of the mixing insert now consists of a single, massive stainless steel piece – without losable parts such as nuts and bolts. The wings of the mixing insert are equipped with pluggable spring clip brackets that can easily be removed for cleaning and then attached again.