Although not widely known, powerful rare earth magnets are also used in process industries to remove small metal contaminants from product streams.

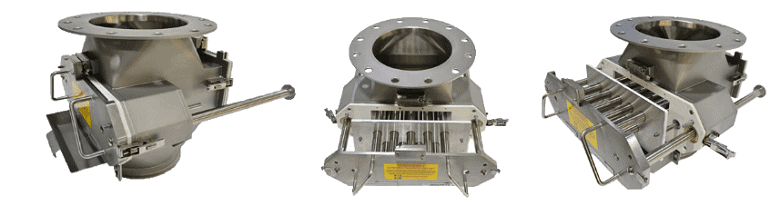

As designs and magnetic strengths have improved over recent years with the introduction of rare earth magnets, magnetic separators are now considered to be critically important process equipment in the food and pharmaceutical sectors.

Typically magnets are used in the primary (raw material intake) and secondary processes (production) while metal detectors are used a final check at the end of the process. As well as helping to eliminate batch rejection, magnets also have the advantage of protecting high value machinery from costly repairs and act as an alert to possible damage by collecting broken parts of the process equipment. Magnets are not considered to be an alternative to metal detectors but as an additional control mechanism.

Bespoke Solutions

Greenwood Magnetics design and manufacture bespoke magnets for a wide range of industries including

- Food processing and production

- Pharmaceuticals

- Powder handling

- Ceramics

- Glass

- Plastics

- Recycling

- Textiles

- Wood

- Oil and gas

- Animal feed

With our primary area of expertise in high-specification magnetic separator solutions for the food and pharmaceuticals industries, Greenwood Magnetics are developing an enviable reputation as leaders in our field.

Greenwood are preferred suppliers to the many of world’s largest food corporations and we export worldwide.

Ongoing Research & Development

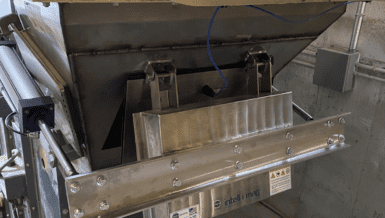

We are also proud of our R & D capabilities. Below is a recent example of our Semi Automatic Grid Box for gravity fed free flowing granules and powders.

National Standards Requirement

Magnetic separators are now deemed so important that the BRC (British Retail Consortium) requires that all food companies test and document their magnets on a regular basis. Procedures should be put in place for the inspection, cleaning, strength testing and integrity of the magnets.

Greenwood Magnetics offer these services and are the UK leader in magnet testing to BRC requirements.