Manual cleaning

For mixers not equipped with cleaning-in-place systems, human intervention is mandatory.

Two solutions are available:

- The use of vacuum cleaners or blowers to suck up/blow away powder residues.

- The use of water or a detergent solution to avoid cross-contamination altogether. However, this can lead to increased humidity in the tank if it is not completely dried.

Manual cleaning is more time-consuming than automatic cleaning, and also requires an operator to open the machine for cleaning. To facilitate this task, the mixer must therefore be easily accessible, easy to clean and have a low retention rate.

Automatic cleaning

What is a Cleaning in Place (CIP) system?

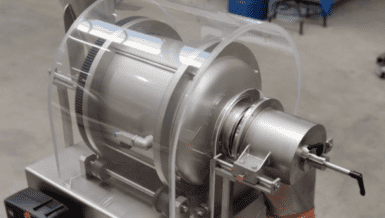

Cleaning-in-place (CIP) systems are automated methods used in powder, paste or liquid product manufacturing industries to automatically clean production equipment such as industrial mixers. These systems enable tools to be cleaned without dismantling them, considerably reducing cycle times and associated costs.

This process is carried out in two ways, depending on the type of product:

- Dry cleaning-in-place with pressurized air blowing for powdery products.

- Liquid cleaning-in-place with pressurized spraying of a cleaning solution (water or detergent) for pasty or liquid products, or for powdered products with special production constraints (organic certifications).

In both cases, nozzles are positioned to clean the tank, tools, main shaft and chutes.

CIP systems enable continuous control of parameters in the cleaning process (duration, action, detergent concentration, temperature) to achieve optimum, consistent cleaning performance.

Initially used in the food industry, the performance and efficiency of these systems have encouraged other industries with cross-contamination constraints to adopt this solution. Today, CIP systems can be found in the building material industry (for colored products), specialty chemicals, oil industry, cosmetics or pharmaceuticals.

Why equip your industrial mixer with a CIP system?

The advantages of using CIP are numerous:

- Guaranteed compliance with the strictest hygiene standards

- Automated system = reduced operating costs

- No interruption to your production process = increased production capacity

- Maximum cleaning efficiency with short cycle times

- Parameterization of cleaning and decontamination functions possible…

- Minimized operator risk

How does a CIP system work on your industrial mixer?

After discharging, a network of ramps and nozzles blows compressed air or sprays a cleaning solution (detergent type or hot water, depending on the manufacturing equipment) into the mixer tank.

The cleaning sequence is predefined and takes place with the tools in motion to ensure thorough cleaning.

In the case of dry cleaning-in-place, nozzles blow pressurized air to lift potential residues and push them towards the discharge hatch. A vent system draws out any dust remaining in the tank.

For humid cleaning in place, nozzles spray the solution onto the tools and the tank, while rotating heads to avoid shadows and optimize cleaning. The mixers are equipped with a wastewater evacuation system after tank cleaning.

At Sofraden, CIP is available as an option on our paddle mixers, ribbon mixers and reactor/dispersers. Configuration varies according to application and mixer, and we can tailor the system to meet your specific requirements.

Some applications

- Coloured dry mortars

- Tile adhesives

- Cosmetic creams, make-up products

- Flours

- Food supplements