In fact, the particle size distribution (PSD) is one of the most important parameters in the manufacture of pharmaceuticals, however, it is quite difficult to achieve a particle size below 1 micron through controlled PSD with standard jet mill technology.

To watch the video, click HERE

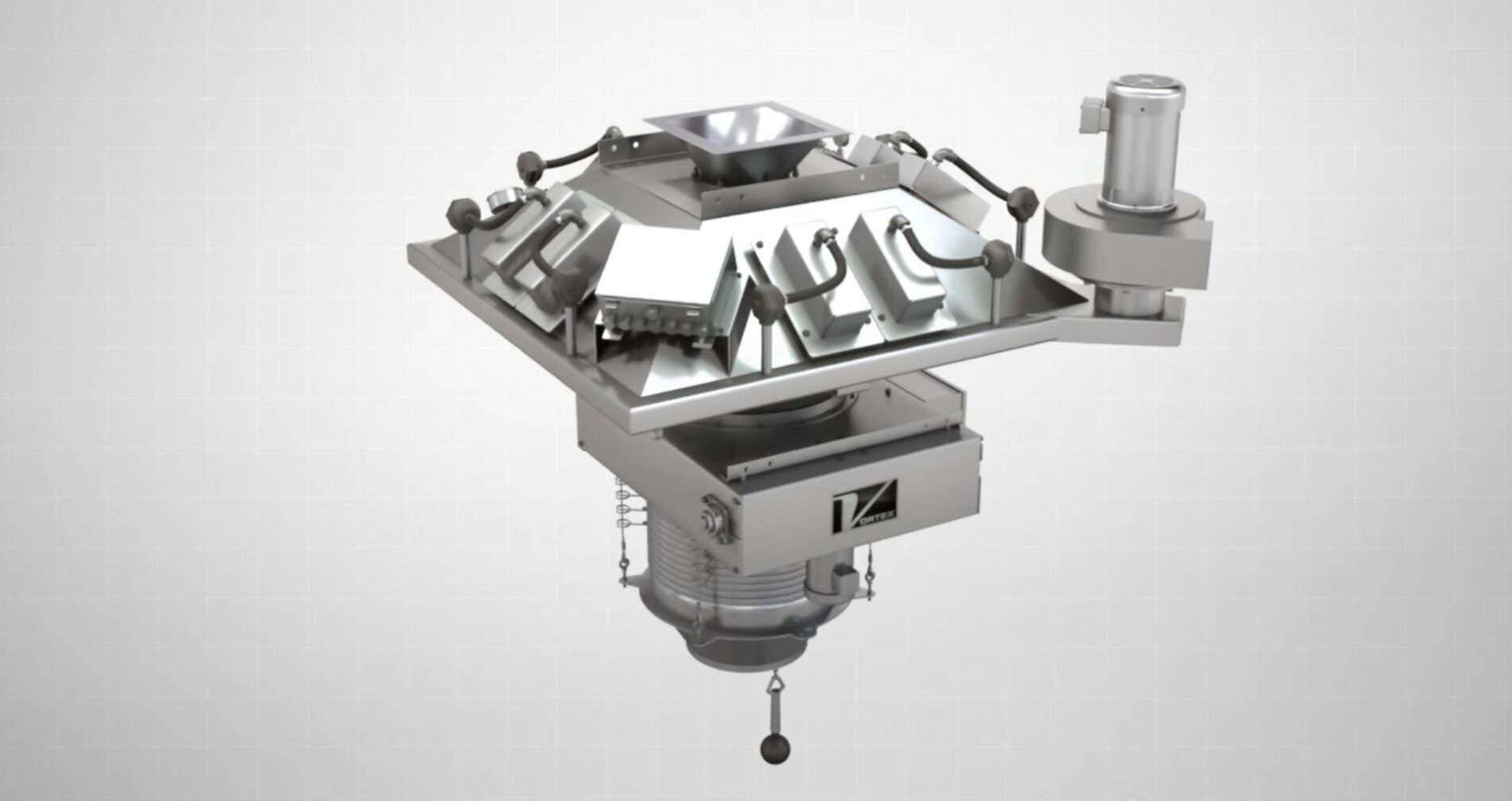

New generation MC DecJet® spiral jet mills

Dec’s new generation of micronizing method – MC DecJet® – is revolutionizing existing micronizing procedures through improved geometry of the grinding chambers and improved nozzle arrangements, allowing companies to obtain powders with a very narrow particle size distribution (PSD). Input APIs are charged from the charging isolator and fed via gravity into a dedicated micronising isolator and into a gravimetric feeder, which introduces the potent powders at a correct mass flow rate into interchangeable MC DecJet® 200 and MC DecJet® 300 systems mounted on slide rails. The chamber provides double-sided access to the jet mill and the gravimetric feeder all mounted on rails for operation ease.

Gas-product separation is performed in a high containment cyclone filter unit chamber incorporating full differential pressure control with automated filter sleeve shaking. The exhaust gas exiting the cyclone is filtered through a double push-push exhaust HEPA filter and an integrated continuous liner system waste port maintaining high containment and overall high safety when removing the filter. From an ergonomic perspective, this cyclone chamber also allows for a double-sided access.

MC DecJet® technology allows micronization plants to obtain a range of valuable and tangible benefits:

- Narrow Particle Size Distribution (PSD) & high product yields via single pass technology

- Superior heat control

- Scalability from laboratory up to production

- Flowability – ideal to handle the most problematic sticky, brittle or very hard substances while minimizing blowback issues and product build ups

- High containment & sterile manufacturing

- Easy to clean (CIP) & easy to assemble (no tools required)

- Easy integration into existing production plants

Dec Group offers a range of MC DecJet® models, which can be easily integrated into an existing production line.

With the group’s unique PTS Powder Transfer System® technology, micronized sensitive powders can be transferred, mixed and discharged with ease from and towards any process step with no leakages, contamination or physical property changes.

If you have any questions or inquiries, contact us info@dec-group.ch