This extraction also requires extreme amounts of energy in the form of e.g. burning fossil fuels. All these activities have pollution either in extraction, production, waste materials, or recycling processes. Therefore more and more companies are contemplating how to use sustainability in their production processes as a tool for growing profitability to comply with regulations and as a guide for future upcoming market opportunities.

Particle science

Here is where particle science plays a crucial role in developing increasingly complex multi-component technological production and end-user systems. The efficiency of a system governed by particle science is really the focus since productivity is paramount in our present exponentially growing technological era that is becoming more focused on creating greener methodologies for our hunger to expand and improve our planet’s ecosystems and the well-being of our species.

The advancements in particle science and the technology field focus more and more on environmentally friendlier processes. The role that it is playing in the enhancement of production plants and systems is paramount, therefore we at DSS strive to aid in the imple-mentation of those improvements and manipulation techniques that are specifically designed for particles being used during a more sustainable fabri- cation process.

All of this eventually leads to the end-user product we all use today such as solid-state batteries, microchips, pharmaceuticals, food/ feed, construc- tion materials to name but a few that are getting less and less of a carbon footprint.

Particle technology is an area of research that focuses on the handling and processing of particulates ranging from nanometers to centimeters in an effort to create greener sustainability, ease of processing, and efficiency of a given chemical transitory process where said powder technology and innovation is being applied in a wide variety of industries. Particles have electrical charges positively charged, negatively charged, or neutral, when both are present. When combining different particle solids energy transition will occur. This transition can be adversely affected by the quality of the substrate, particle size, particle purity, particle additives. With stricter regulations, science needs to become greener to support the 2030 global sustainability goals set out by the United Nations. Delft Solids Solutions helps with that goal and helps industry partners to streamline their production in a greener direction.

Regulations becoming more stringent

In recent years the growing focus on sustainability initiatives has gained more awareness and has branched out and perforated in many industries. This has led to an increasing number of improved production standards and more stringent regulations with the focus on addressing the social and environmental consequences that come with resource extraction, production, and recycling.

These standards and regulations enforce existing and upcoming technologies to adhere to greener extraction and production methods enabling particle technology to find design solutions. Delft Solids Solutions is specialized in technical research, testing, and identifying solutions to help and support industries to find better ways of resource raw material extraction and technological production methods that comply with stringent regulations that are aiming to lower pollution and transition into more sustainable technology. An example of energy transition towards sustainability is the electric car battery industry.

Lithium ion’s a transition phase to a greener world

Improving the efficiency of electrochemical energy storage systems such as lithium-ion batteries is a drive towards a greener, more sustainable future. This is one example of energy transfer in solids and the electro- chemical potential it can generate. Lithium in its pure form is a highly reactive element but by adding an alkali metal oxide like carbonate, the lithium becomes lithium carbonate and is much more stable and can be used in many areas of industry, in this example, to facilitate electricity trans- ference in a battery.

Lithium has a high tendency to lose the outer electron. When this happens, the lithium discharges electricity from the anode, which releases a flow of lithium ions to the cathode generating electron transference.

This process has been improved over the years and is still improving by using powder and particle technology to enhance the efficiency, with the aim of a more environmentally friendly energy source; an example is using NMC Nickel manganese cobalt to facilitate electron transition from anode to the cathode through an electrolyte. The study of these particles, their behavior, size, and positioning is paramount in improving the efficiency of the system, laboratory research focuses on improving the flow of the particles by solving heat buildup, overheating, clumping of particles, a better transition of electron flow by improving the medium layers and chemical structures of the substrate, in essence looking for the particle sizes and chemical reactions that best contribute to a more efficient energy flow which essentially benefits the environment in the long term.

Macro and micro-meso perspectives

Battery macro-scale performance improvements in electric car batteries or our phones are only possible due to micro and mesoscale reactions. There are several widely used techniques to study electrode materials for battery applications and they are making significant strides to observe process samples in situ, which provide particle-level insights into dynamic battery material functions at the atomic resolution.

These reactions can be seen using several different techniques which allows us to collect data to find lags or loss of energy which inevitably improves the particle transition. This data helps us explore how different particles sizes and their locations on the medium could affect the discharge process of the lithium-ion particles. This benefits the fabricator by helping to improve the efficiency of the energy transition.

Modifying the particulates to solve observed phenomena and where there could be a degradation of efficiency such as overheating or inefficient particle distribution helps all of us. The aim after all is to work towards a more efficient and greener energy transition with a prolonged battery storage duration which benefits our technology usages and the environment.

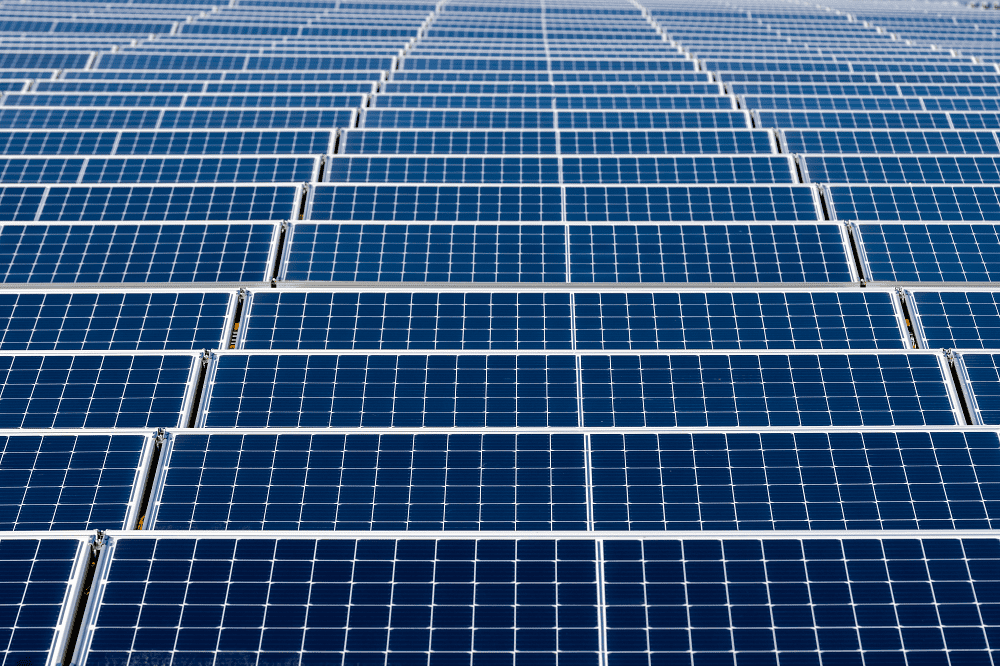

Solar panel energy transition

Another example of renewable energy transition made possible through particle technology development is in the advancements of greener and more efficient electrical transition between anode and cathodes in Copper Indium Gallium Selenide (CIGS) photovoltaic semiconductor technology, in short, a solar panel. The CIGS thin films are presently an improvement to silicon-based solar panel materials and less toxic than cadmium telluride (CdTe).

The efficiency of these devices is strongly determined by the electrical and optical properties of the films designed and tested by powder technology research and development laboratories such as Delft Solids Solutions.

CIGS-based photovoltaic cells composed of a positively charged CIGS layer under a negatively charged cadmium sulfide layer are created by evaporating CGIS powder. The powder design and particle size distribution is important in producing a chemical and morphological CGIS P-type layer that is efficient in electrical transition.

Just like in the aforementioned lithium-ion battery and the latter solar panels the different particle size distribution and alloy composition can adversely affect the energy process therefore powder technology is essential in research and development and advancement in our technological era.