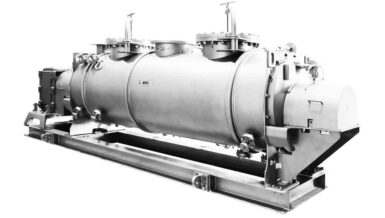

Powder wet-out and dispersion, temperature control, emulsification, homogenization, and degassing are accomplished all in one vessel to produce creams, gels, and pastes in a highly repeatable and clean mixing process. Featuring electropolished and passivated product contact surfaces, the VersaMix pictured below is designed for full vacuum operation as well as internal pressure up to 5 psig to accommodate nitrogen blanketing. This ROSS model has an ASME-stamped mixing vessel supplied with a matching platen-style discharge system. CE-marked motors and ATEX-rated operator panels are suitable for use in a Zone 1 classified area. These features are available across the entire suite of VersaMix sizes ranging from 1 to 500 gallons. Larger models in a fixed-tank configuration are available as well.