The total energy discharge of a person is about 10mJ. Likewise, small items such as metal buckets can be easily charged to an energy level of a few mJ, which is already more than the minimum ignition energy (MIE) required to ignite most flammable vapors.

It is therefore not difficult to imagine that the energy discharge of a charged truck or bulk truck can reach up to 100 mJ. The above makes it clear that the correct earthing of a truck during loading is crucial.

For example, if a relatively small truck with a capacity of 1000 picoFarad is charged to 14 kV, it has a potential spark energy of 100mJ. Most hydrocarbon vapors and gases have MIE’s of less than 1mJ, it is clear that any tanker without proper earthing will be large potential ignition source in a hazardous area.

Norms and standards:

The available standards, especially IEC / TS 60079-32-1 (Electrostatic hazards, guidance), describe processes where static charges can be generated, such as loading trucks and train wagons, filling and emptying of mobile tanks and vessels and mixing / mixing and transporting substances. Other relevant standards: NFPA 77 (Recommended Practice for Static Electricity) and the API RP 2003 (Protection Against Ignitions Arising out of Static, Lightning, and Stray Currents). This standard specially highlights the loading of trucks, railway wagons, storage tanks and general work at petroleum products.

According to standards, effective earthing is the primary preventative to prevent hazardous electrostatic discharges and is the simplest, safest and most cost effective way to ensure that static hazards are properly controlled. Safely getting rid of static build-up will eliminate the risk of static discharges.

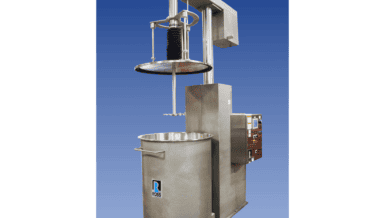

Truck earthing unit

IEC/TS 60079-32-1 only indicates that an earthing cable must be provided. In theory, a cable would therefore suffice.

Nevertheless, to avoid forgetting to earth the truck, an interlock earthing unit is recommended.

The truck may also already be electrically charged upon arrival at the unloading site. Hence, with a good earthing unit, the clamp should ideally be insulated from the ground, and only connect to the “earth” after the clamp is connected to the tanker. This prevents the generation of a (potentially dangerous) spark when the clamp is attached to the truck.

The TES01 truck earthing system is available in two versions:

- TES01/IP (suitable for installation in ATEX zone 22)

- TES01/EX (suitable for installation in ATEX zone 1/2)