Chips, Tortillas & Wraps

As part of a push to speed up and improve production, Gough received an inquiry from a food product manufacturer looking for sieving and conveying various ingredients. The manufacturer is a major supplier of Mexican foods such as chips, tortillas, and wraps in the UK and Europe.

Loading the Mixer Manually

Making tortillas and wraps involves emptying 25kg bags of flour and other ingredients into a mixer.

The mixer used is a large industrial unit with an inlet height of over 2,000mm. Access to the inlet is via a set of steps and a small platform. Originally the operators carried the 25kg bags up the stairs and had to lean out over the inlet of the mixer to load the product.

This process created multiple problems:

- Carrying heavy bags upstairs can be hazardous, leading to health and safety issues

- It is a slow process which ties up operators from other work

- It is strenuous, and only achieved by certain operators

- Emptying the bag directly into the mixer can mean debris, such as pieces of bag and bag string, falling into the mixer leading to reject the product, increasing waste and cost

Process Improvements

Fed up with operating the mixer manually, the manufacturer set three goals to improve the process:

- Supply a conveying system to allow bags to be emptied at ground level, so operators no longer had to carry the bags up the stairs

- Include a screening system to prevent debris from reaching the mixer

- Make the whole system mobile, so the system could be used to load multiple mixers

The Partnership Solution

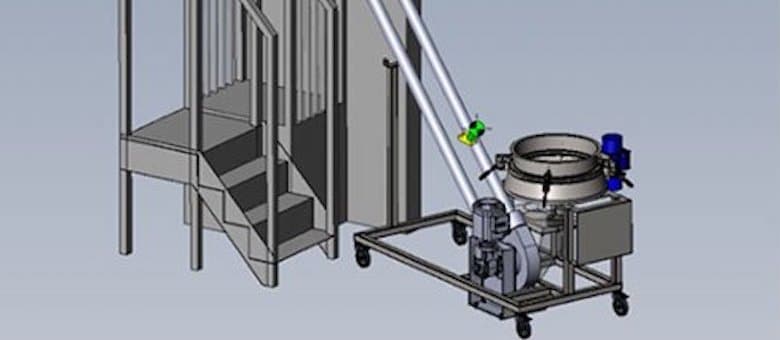

- Gough supplied a system including a vibrating batch sieve, Floveyor aero mechanical conveyor, and mobile support frame

- Operators can now open and empty the sacks into the vibrating sieve at ground level

- The sieve filters out any debris and sieves flour empties into the inlet of the aeromechanical conveyor

- It connects to the inlet of the aero-mechanical conveyor by an airtight flexible connection, ensuring no spillage or waste

- The Floveyor moves the flour along a stainless-steel pipe before discharging into the open inlet of the mixer

- The system enables the mixer to be loaded with the specified ingredients in less than four minutes

- While the mixer is processing, the conveying system can be wheeled into position to load the next mixer

Customer Feedback

Since putting the first system to work, the customer has ordered two additional units to feed mixers on a new production line.