Wet and dried sludge that has been mixed and treated inside a Ploughshare® Mixer in a continuous process boasts a pumpable consistency, exactly the right moisture content required to achieve the necessary calorific value and a particle size that ensures the perfect consistency. This provides reliable protection against the sludge sticking or turning into a paste. Additives such as lime can also be added in easily during processing.

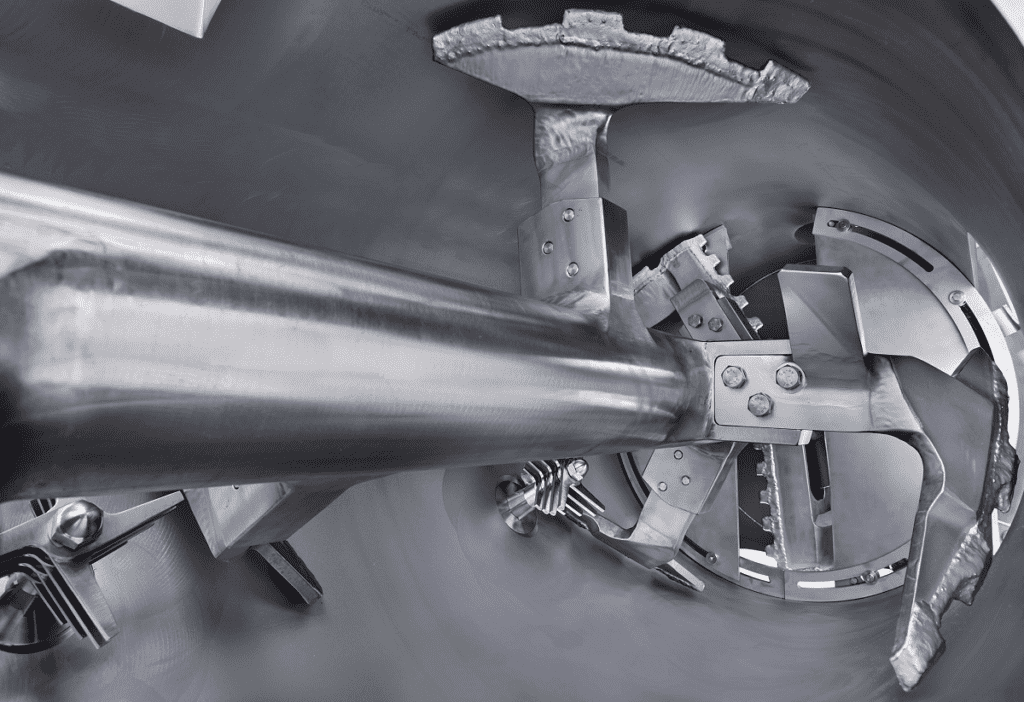

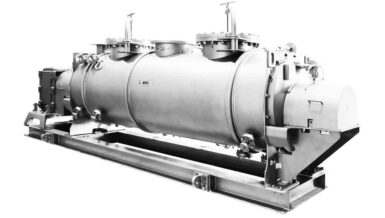

Lödige Ploughshare® Mixers have already proved their effectiveness in sludge treatment in many different places. They operate based on the fluid bed principle that ensures a very good mixing performance and was introduced to industrial mixing technology by Lödige Process Technology: the specially developed shovels rotate close to the wall inside a horizontal drum, creating a fluidised bed. The process enables a high degree of homogeneity and constant reproducibility.

Intensive forced mixing and other benefits

Treatment inside a Ploughshare® Mixer brings multiple advantages over other ways of treating municipal or industrial sewage sludge: intensive forced mixing coupled with short process times enables efficient operation that produces unbeatable results. The desired consistency can be adjusted as required. Retention times, duration of treatment and other process variables can be modified depending on the characteristics being sought. The rugged design ensures a long useful life and keeps maintenance to a minimum and the material used for the mixing drum can be chosen based on the specific sewage sludge – from carbon steel through to high-quality stainless steel. Ploughshare® Mixers come in various different sizes and are also available in an explosion-protected version for specific applications.

Lödige at IFAT 2022 – 30 May to 3 June 2022 – Munich Trade Fair Center, Germany: booth A2.520