The basic machine weighs the load above the bag, the operator then hangs the bags to the machine fill pipe. The bags can either be sealed or sewn shut.

In general, these units work with one or two weighing scales above the bag fill pipe. The small bag is hung with a bag clamp to the fill pipe and the correctly weighted product falls into the bag. Once full, the clamp releases the bag and it is transported by a conveyor to the closing system. The capacity of this line is between 1000 – 1200 bags/hr for two weighing scales and one fill pipe. When this machine set up is based on one weighing scale and one fill pipe, this capacity is reduced to 600 bags/hr.

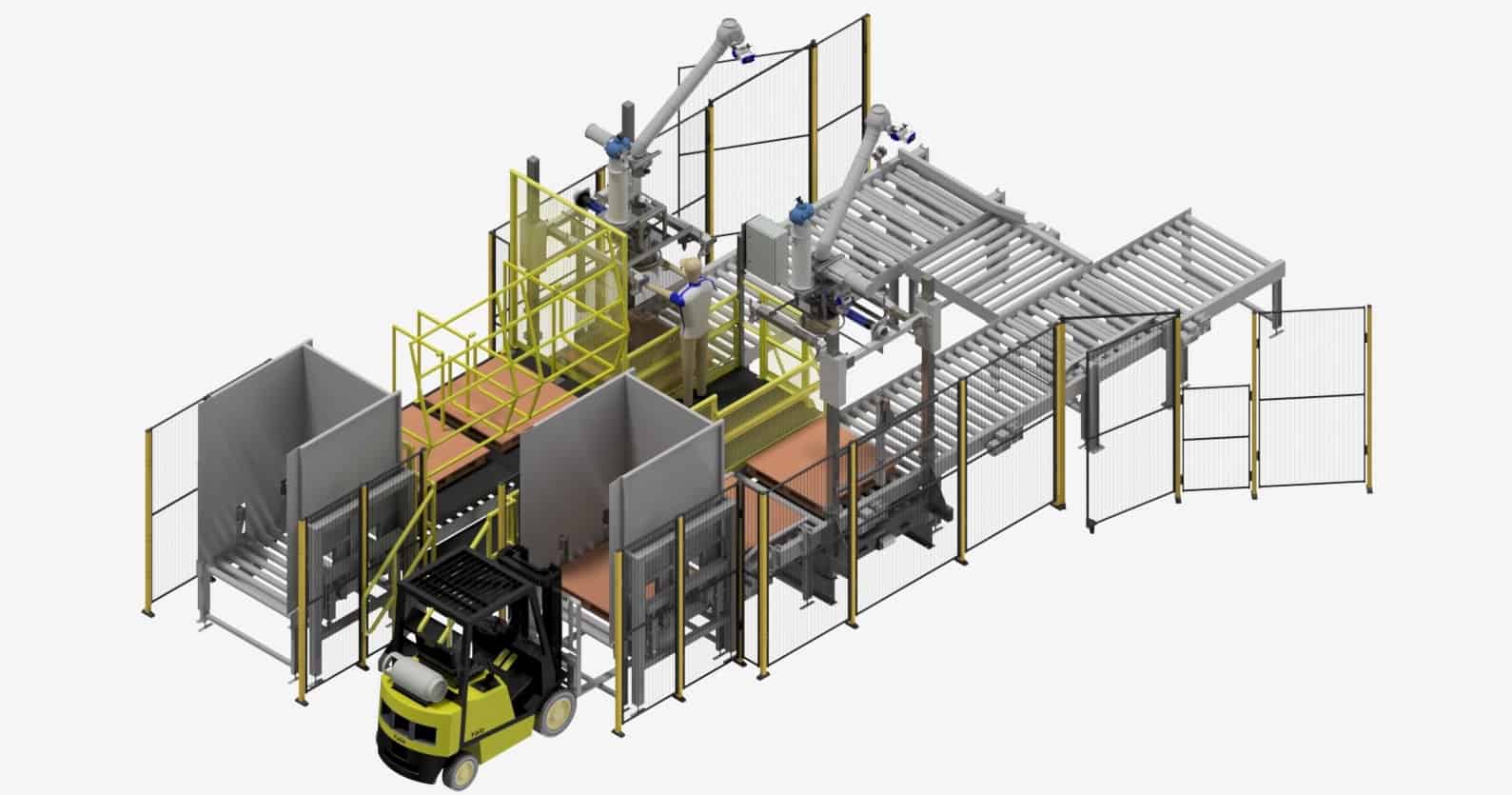

The machines described above are constructed as open mouth bag fill machines. Some users also use valve bags, where the bag is not open, but preformed and closed with only a fill opening at the top side of the bag. This type of filling method takes more time as the pipe is a maximum of 8 cm wide. There are several robotized bagging lines available. This usually means that robot arms are used for loading open-mouthed or valve bags, or fully automatic lines like the role form fill seal machines (RFFS). These machines are fully automated and the polyethylene bag is stacked on a roll.

ln general, most fertilizer handling machines are constructed of stainless steel 304. This reduces the chances of the machine rusting.

A further advantage of automatic bagging systems is that they often have climate control features to take away moisture, so these lines are often installed in closed conditions where moisture is regulated by air conditioning or air dryer systems.