The storage capacity of big bags, Jumbo bags, or FIBC bags used for holding fertilizer can range from between 100 –1000 kg or more. Due to these differences in size and variations in handling requirements from country to country, a range of different machines is required for fertilizer bagging operations.

Different types of machines are needed to fill these bags; fixed machines, portable machines, and net or gross weighing systems. The capacity that these machines are capable of handling per hour can vary, as can the filling methods.

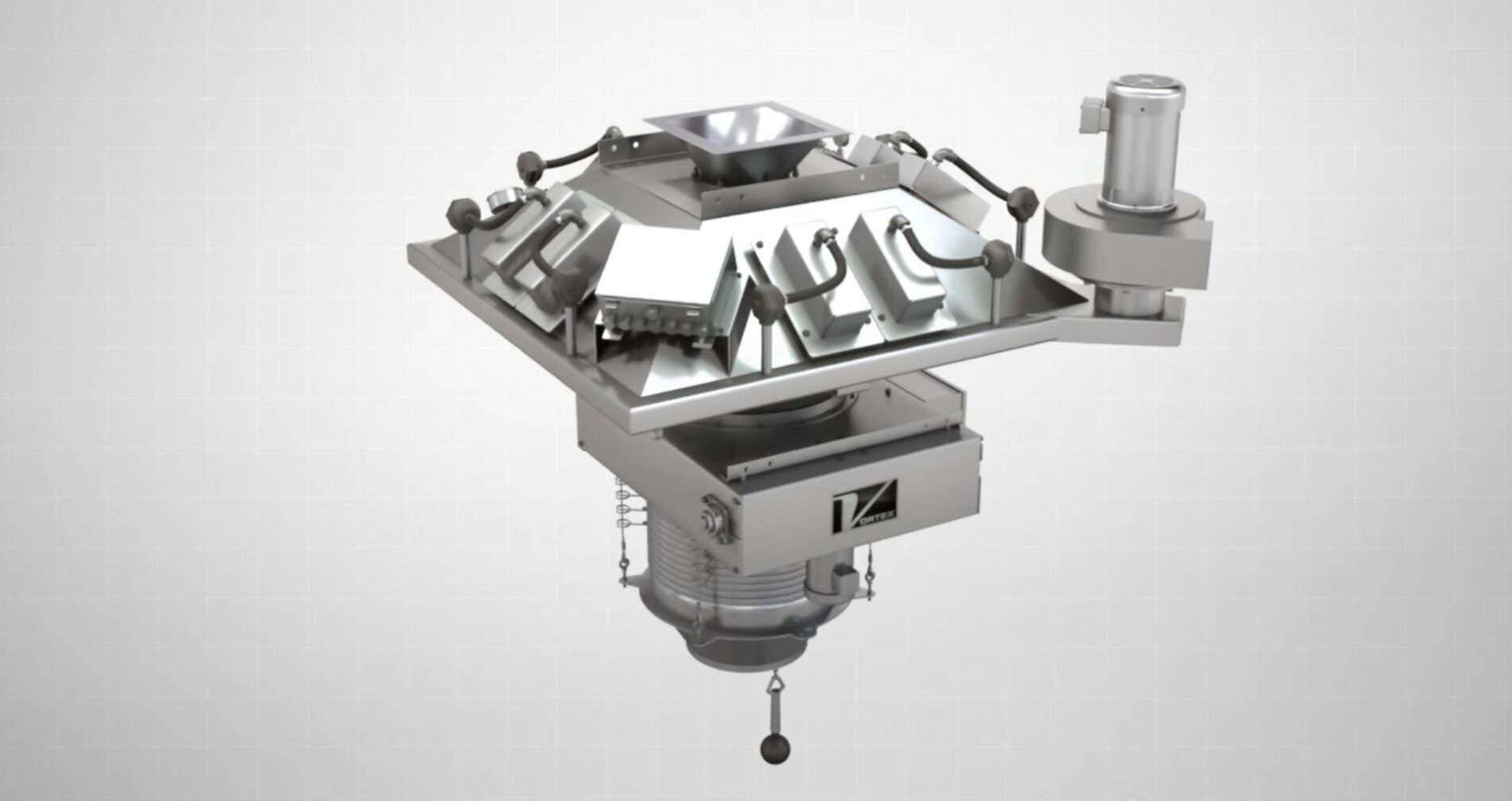

Generally, the system of choice is a gross weighing system, where a digital scale is placed on the floor and the bag is filled with the fertilizer by an automatic metering slide or valve. However, the handling is done manually. The scale measures the empty weight of the big bag. All the systems described in this article are capable of handling bags with either one, two, or four-loop bags.

The gross weighing big bags systems have a handling capacity of 30 – 60 bags,/hr for 500 kg bags, which is also the same for 1000 kg bags.

The EMT High-Speed big bag line weighs loads above the bag; this is called a net weighing process. Then, a weighing hopper is installed above the big bag and the product that needs to be filled is pre-weighed. These net weighing scales commonly handle volumes of, 1500 l, however they have the capacity to fill up to 1000 kg for light density fertilizer. This type of high-speed net big bag fill system can fill up to three big bags of 500 kg/min.

A variation of these gross or net weighing systems in a warehouse is the portable big bag fill line, which is produced inside containers. lt is possible to move these containers to the product instead of bringing the product to the machine. This type of machine can be installed in l0 ft (3 m),20 ft (6 m), or 40 ft (12 m) containers. The handling capacity of these systems is the same as that of the fixed machine lines. The benefit of these portable lines is that they are very flexible. These portable lines can be used in warehouses and shipyards so that bulk cargo can be discharged from the ship and repacked.