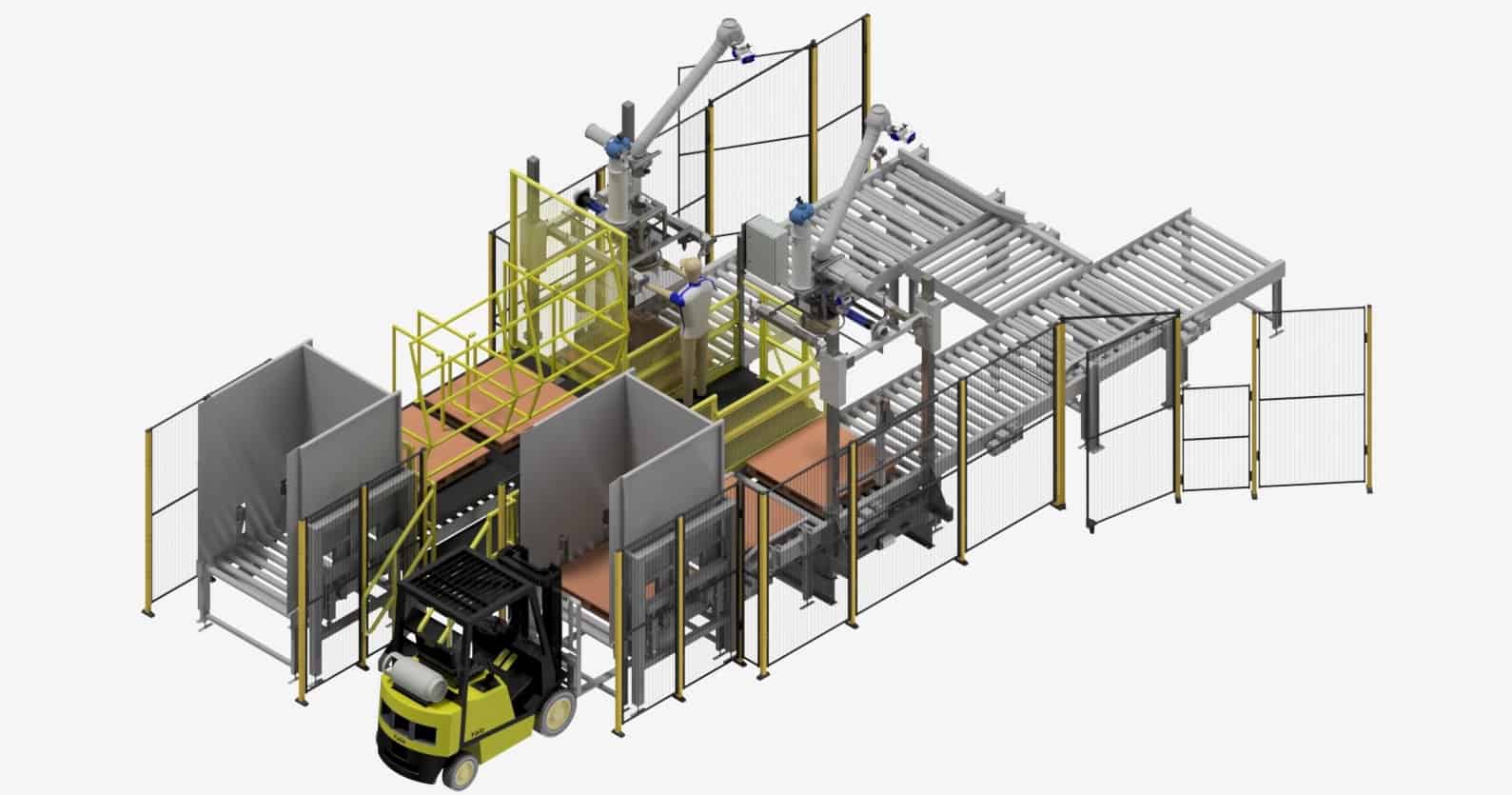

The mobile big bag discharge and bulk truck loading system can be moved using a towbar or a folklift for easier and safe transportation. This system is an assemblance of various components. These include a big bag discharger, a screw conveyor, an electrical panel, a dust collector, screw jacks, an air compressor, a chassis, a loading bellow etc.

The system is towed to the loading site where it is positioned appropriately. The screw conveyor is elevated to an adequate position (– about 45° from its initial position). The inlet port of the bulk loading truck is positioned right below the telescopic chute for a precise fit between the chute’s polyurethane coated discharging cone and the truck’s inlet port. At this point the chute is lowered towards the truck’s roof and stops at the inlet port. The big bag is transported using the forklift and placed on the discharging hopper with an inbuilt knife which pierces the big bag instantly and starts the discharge of the bag. In the case of a big bag having an emptying spout, an operator unties the spout for the bulk material release. The bulk material released from the big bag to the hopper is passed to the screw conveyor where it is conveyed to fill the bulk truck. The bulk material is supplied to the truck through a loading bellow.

During loading, dust is emitted within the system. The emitted dust is seized by the dust collector which is connected to the bellow and the hopper. The dust trapped on the filter units is sent back to the hopper with the aid of the automatically controlled pulse jet valves.

With the help of the level sensor placed at the chute’s outlet, the loading stops when the tanker is full. The sensor monitors the bulk material levels. The telescopic chute automatically retracts to its initial position a few minutes after the loading process finishes. This is to ensure complete seizing of the dust. The operator brings back the system to rest by using an electrical control panel. All the components of the system are customised with respect to the application requirements.