Explosion Protection & Process Safety

Our latest E-mail campaigns for Explosion Protection & Process Safety

- February 19: Explosion Protection and Safety Insights February 19, 2026

- October 16: Explosion Protection and Safety Insights October 16, 2025

- June 19: Explosion Protection and Safety Insights June 19, 2025

- February 20: Explosion Protection and Safety Insights February 20, 2025

Experts for Explosion Protection & Process Safety

Sylvain Bellamy

Tetra Pak Powder Process & TechnologySylvain Bellamy is currently the Commercial Director for Powder Process and Technology at Tetra Pak, based in France. With over 25 years of specialized experience in powder processing, handling, and packing, Sylvain has held various roles across the Americas and Europe, providing him with a comprehensive understanding of the global market. Sylvain's robust background in the food processing industry has sharpened his powder expertise during his years at Tetra Pak, where he contributed to developing innovative powder processing solutions. He leverages his extensive experience to drive strategic growth and operational excellence, always ensuring the delivery of cutting-edge technology and solutions that bring innovations to the market. Contact: Sylvain.Bellamy@tetrapak.com

Johannes Lottermann

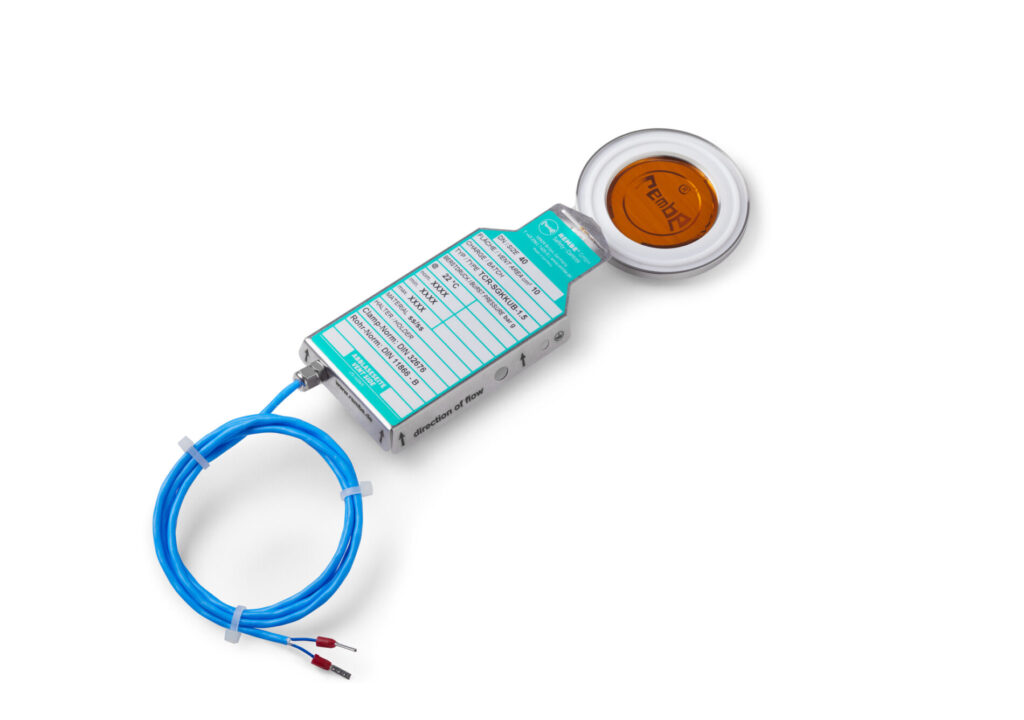

REMBE® GmbH Safety+ControlDr.-Ing. Johannes Lottermann studied safety engineering before he worked for DMT GmbH & Co. KG, an independent engineering and consulting company. He managed the department of technical fire and explosion safety. In 2010 he started to work at REMBE GmbH Safety + Control and is in his role as Director Explosion Safety responsible for the (inter)national customer base with a focus on consulting and engineering. Johannes Lottermann is a member of numerous expert committees and international professional associations such as the VDI, VDSI and VGB.

Emre Ergun

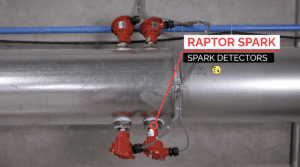

IEP TechnologiesEmre Ergun is the Head of Sales of IEP Technologies Europe. He brings over 24 years of experience in the industrial explosion protection and prevention field, specializing in explosion suppression & isolation systems, venting (including flameless venting), and spark detection & extinguishment solutions. He is also experienced on dust explosibility testing methods, applications and relevant standards. He holds BS Chemical Engineering from Middle East Technical University, Ankara, MS Engineering Management from Northeastern University Graduate School of Engineering, Boston MA and MBA from Babson College, F.W. Olin Graduate School of Business, Wellesley MA USA. Mr. Ergun is a certified safety auditor (CSA) by the National Association of Safety Professionals, NASP.

Pablo Balan

Boss Products, LLCDesign Engineer, Project Manager, Territory and Sales Manager with 40+ years of experience in capture at source designs, sales and installation projects for high and low vacuum and dust collection and filtration systems and explosion and fire mitigation in dust collection systems.

Matthew Bailey – Technical Lead

BFM® Global Ltd.Matthew is a mechanical engineer holding an honours degree from the Auckland University of Technology and has been responsible for BFM® Global’s product development, testing and compliance programme for over 7 years. Matt’s experience is centred on the powder handling industry with a specific focus on flexible connectors, and all the compliance requirements around them. From food to pharmaceutical and all industries in between, Matt works with our Distributor partners, end users and OEMs from Europe, Asia and the Americas to solve application challenges. He regularly attends industry tradeshows around the world and understands the complex requirements of each different market.

Karen Van Aelst

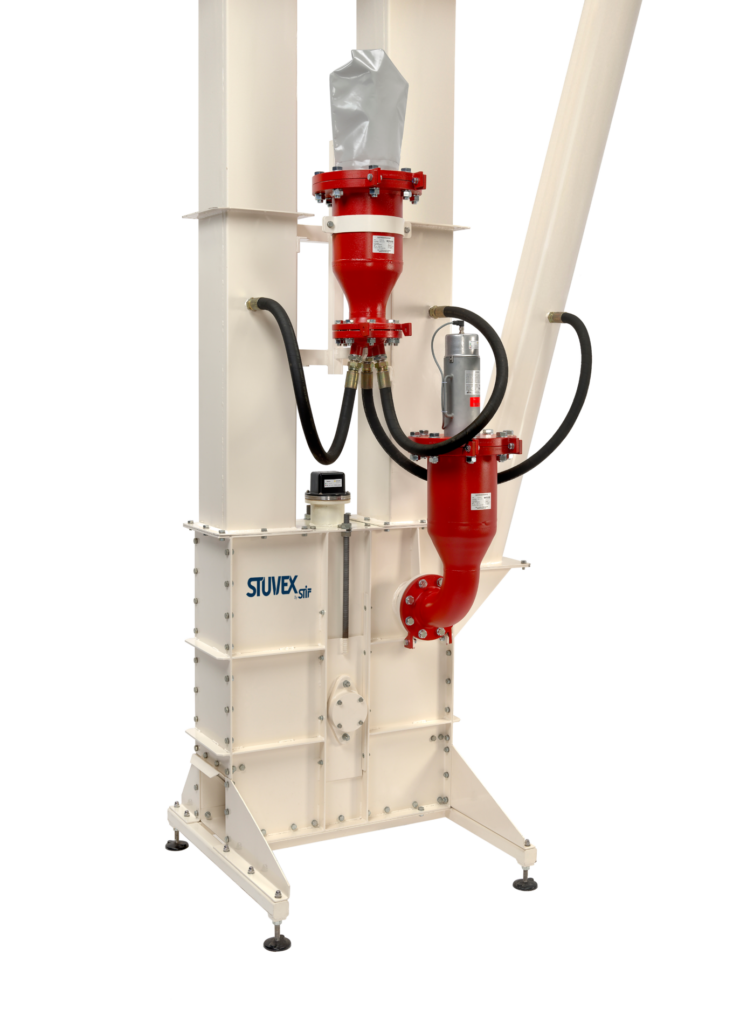

Stuvex International NVKaren Van Aelst, ing., is a seasoned professional with a rich background in sales and engineering, particularly within the dry bulk handling and process industry. Over the course of 12 years, she honed her expertise in selling installations tailored for these sectors. In 2010, Karen transitioned to StuvEx, where she embarked on a decade-long journey as a sales engineer specializing in explosion protection. Her role encompassed managing sales activities in both BeLux and Germany, showcasing her proficiency in navigating diverse markets and establishing strong client relationships. Since 2019, Karen has assumed the position of Product Manager at StuvEx, where she is entrusted with the vital responsibilities of overseeing the development and market realization of explosion protection products. Her extensive experience in sales, coupled with her engineering background, positions her as a valuable asset in driving innovation and ensuring the safety of industrial environments. Karen's dedication and expertise continue to play a pivotal role in the success of StuvEx in the field of explosion protection.

Powders and bulk solids are handled and processed widely in chemical, pharmaceutical, food, milling, dairy, agriculture, plastic, mineral, and other industries: these dry materials’ handling operations imply the processing of unique fire, explosion and toxicity hazards. Substances practically inert in consolidated form can become quite hazardous when converted to powders and granules.

There are two European Directives in place for the control of explosive atmospheres: Directive 1999/92/EC (also known as ‘ATEX 153’ or the ‘ATEX Workplace Directive’)

There are two European Directives in place for the control of explosive atmospheres: Directive 1999/92/EC (also known as ‘ATEX 153’ or the ‘ATEX Workplace Directive’)