That’s (more or less!) how Greg Thompson, COO and technical expert at ACS Valves, invented the new Multi-Port valve. Inspired by trough-style feeders, Greg set out to make their design more compact and configurable for different applications. He came up with the Multi-Port, which features separate airlock compartments for improved NFPA compliance, uptime and efficiency. It’s the first and only one of its kind in the industry. If you plan to convey high volumes of material or run independent feeds, you’ll definitely want to read up on this valve.

What’s a Multi-Port valve?

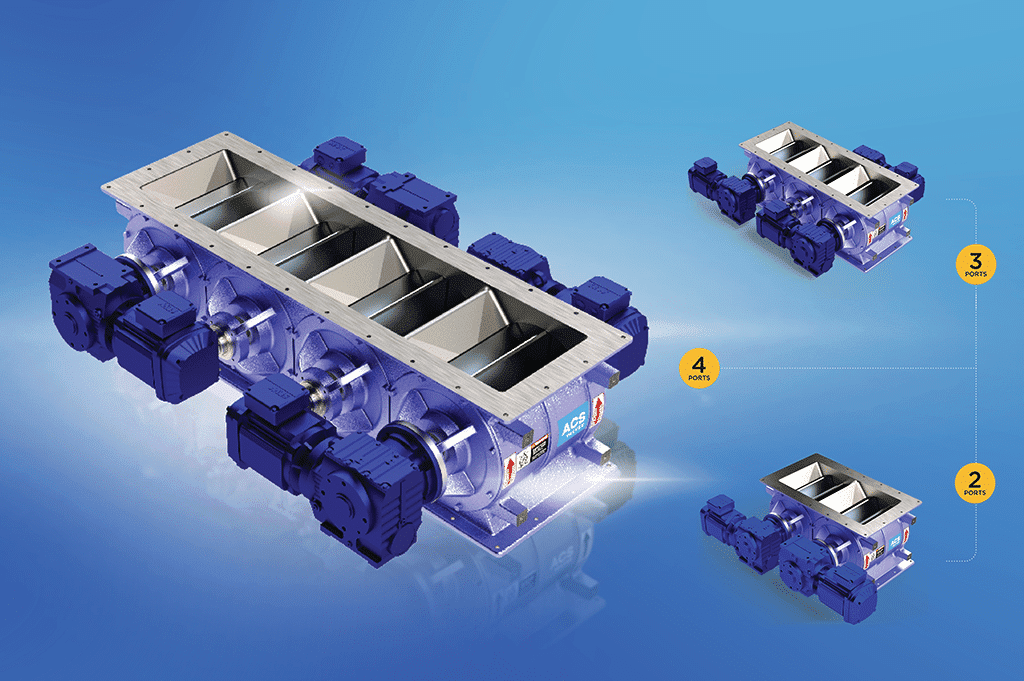

Imagine a trough-style feeder valve, but instead of one long compartment, it’s broken into several smaller ports. It’s pretty much that simple. Think of the Multi-Port as one long housing has broken up into two, three, or four separate compartments. Each compartment has its own rotor and direct-drive motor, so they can run independently or all at the same time. The Multi-Port works well in almost any high-volume powder or bulk applications, but it’s especially useful if you convey cement or free-flowing bulk material stored in large silos, such as grains or food additives.

Preaching (rotor) tolerance

If there’s one tune we’re always singing at ACS Valves, it’s the importance of maintaining the correct rotor tolerances. This is a measurement of the space between the rotor and housing, also called the clearances, and is essential for NFPA safety and compliance. Now, high-volume applications often call for larger rotary airlock valves that can withstand high temperatures. The sheer size of these valves makes it tricky to maintain precise clearances. Smaller pieces are easier to maintain and replace, plain and simple. That’s where the Multi-Port comes in handy: the correct NFPA tolerances are much easier to maintain. Because the valve uses common parts, it’s also faster to order replacements. All in all, that means less downtime for repairs and maintenance.

More ports, fewer problems

There are a few different ways to use the Multi-Port valve. You can run all compartments at once, depending on your needs, or run different feeds through different compartments. Or you can simply run one compartment at a time and use the others as backups in case something goes wrong. If things change, you can switch it up at any time. You can use the Multi-Port to separate conveying lines into different bins or just run it as one big trough. If you set things upright, you can virtually avoid downtime, because there should always be at least one compartment that keeps running if there are problems in another section.

Switch hitter

The Multi-Port’s smaller compartments make it possible to equip different accessories and customize it for specific applications. Depending on how you choose to set it up, you can boost efficiency even more with various options from the ACS catalogue. If you’re using the valve’s full capacity, for example, you could use one elongated blow-through adapter and one large pressure blower package to help material flow through the system. Otherwise, you could use several smaller blow-through adapters or pressure blower packages for multiple line feeds.

So many options!

The beauty of the Multi-Port valve lies in its versatility, but you don’t have to figure it all out by yourself. The experts at ACS Valves are happy to help you determine the best configuration for your conveying system. Let us know how we can help!