Why are airlocks necessary?

Airlocks improve the performance of the dust collector system by isolating dust into a contained stream. Rotary airlocks maintain a pressure differential between two separate, differently pressured atmospheres.

Airlocks let operators change the dust bin without shutting off the system. Without an airlock, they would need to shut down the system to get rid of dust, and contaminated particles would be free to enter the environment. It’s important to make sure the airlock is properly designed for this purpose.

What makes a good rotary airlock?

With the right design, a rotary airlock should be able to handle high volumes of dust efficiently, which helps improve air quality, keep machinery clean, and keep the environment sanitary.

To prevent the passage of flames or sparks, it’s extremely important to make sure the airlock is NFPA-compliant.

How are NFPA-compliant valves designed?

Rotary airlock design considers how the conveying system should be configured, the type of deflagration protection to use, and the maximum pressure the valve can handle.

Specific material characteristics will heavily influence the airlock design, but there are some rules that apply in all cases. All airlocks in dust collector applications must comply with NFPA regulations.

NFPA 69 (Standard on Explosion Prevention Systems) has the details on airlock design, but other key codes include NFPA 68 (Standard on Explosion Protection by Deflagration Venting) and NFPA 652 (Standard on the Fundamentals of Combustible Dust).

Here are some key airlock design rules in plain language (NFPA 69 12.2.4.3.1–12.2.4.3.9):

- The valve housing and rotor must be strong enough to withstand the pressure of a possible explosion.

- The valve design must consider the powder’s explosion characteristics.

- An appropriate testing authority must certify the valve’s pressure resistance.

- The rotor must have 6 vanes at least.

- At least 2 vanes on each side of the housing must have adequate clearances at all times.

- The valve’s body and the rotor vanes must be made of metal.

- The valve must have external (outboard) bearings.

- To automatically stop the valve in case of a deflagration, there must be an independent explosion detection device interlocked.

- Check region-specific laws to determine the need for valve performance testing.

Which airlock is the best?

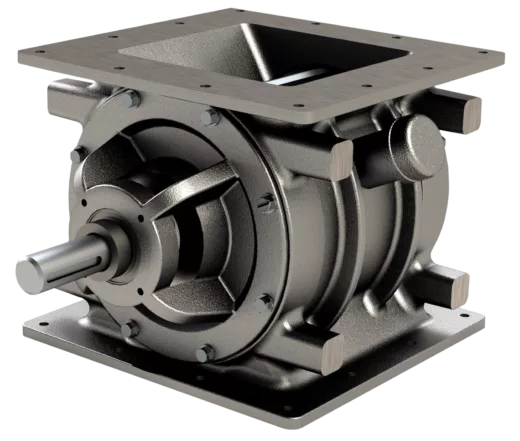

At ACS Valves, we often recommend the CI Series, MD Series, and SD Series rotary airlocks for dust collector applications. A square flange is the most typical. In most average dust collector systems, airlocks are sized at 10’’ or 12’’.

An outboard bearing design eliminates dust leakage from the endplate shaft seal. For a smooth rotation, the airlock should have a rotor with bevelled tips.

If the conveyed material is a combustible dust, the airlock should come equipped with an explosion-proof motor.

What about optional features?

The dust collector valve may need high-temperature clearances, a shear protector to prevent material shearing, or a shear pin sprocket in case of jamming. If the dust particles are abrasive, consider an AR rotor, chrome plating, or Tungsten plating to reduce maintenance cycles.

Which dusts are more hazardous?

Each type of material has different characteristics, and each one in the combustible dust category has a different potential for deflagration.

Annex F of NFPA 68 (2023) has a handy series of tables listing several types of combustible dusts and their deflagration characteristics. The materials are sorted into dust hazard classes. Independent labs can be hired to test and analyze dusts for anyone who is not sure about their material characteristics.

What else can be done to protect workers and facilities?

A regular maintenance schedule is essential. Check rotor tolerances often to make sure they stay under 0.0079’’ and replace any part that looks worn. For plants that handle combustible dusts, a Dust Hazard Assessment (DHA) is required by NFPA codes and will help identify any potential hazards in the facility.

ACS Valves designs airlocks with NFPA compliance in mind. To start a conversation about the best airlock valve for your type of dust, contact our knowledgeable reps.