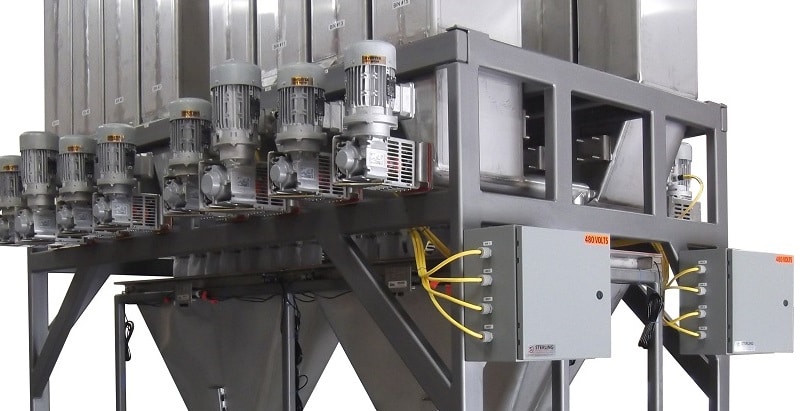

These systems can typically include supply bins, feeders, work platforms, automatic or manual bin refilling, raw material bag lift handling equipment, dust collection/control, batched material conveying equipment (pneumatic and mechanical) or transport totes, lot tracking and traceability, barcode scanning, and RFID scanning. Other customized options can also be included. Micro weighing systems are those which have scale weighments up to around 50lbs (23kg). Larger weighments are known as Minor (50lbs up to 100-150lbs) and Major (> 150lbs). Often a combination of micro, minor and major weighments are included in a customized micro ingredient material weighing system. High accuracy can be attained, to within 0.001lbs or 0.5g is possible, depending on applications.

Sterling Systems & Controls offers a variety of feeding devices for use in the micro ingredient material weighing systems. Typically screw/auger and vibratory type feeders are used. The type used is based upon what the best solution will be for the specific application, including system weighing accuracy required. The scale devices used in the micro ingredient material weighing systems can be of a variety of designs, including hoppers, platforms, conveyors, etc. The scale type chosen depends on application requirements, e.g. scale resolution, accuracy and batch rate. Transfer of the completed batches to downstream processing, such as a mixer, blender or other process equipment, can be done manually or automatically.

Sterling Systems & Controls automatic micro material weighing systems are modular in design, allowing for expansion of the systems as requirements change over time. Systems typically range from 6 to 48 storage/supply bins, with the average being 24 micro ingredient supply bins. It is not unusual to update systems with additional bins after initial system installation. State-of-the-art automation and electrical controls for the material weighing system can be provided. Sterling Systems & Controls custom designs each system using standard components.