Advanced Detection Systems has been identifying and meeting unique metal detection needs for over 30 Years. We manufacture superior reject devices and accessories to meet your application requirements. Any reject device and accessory can be customized or designed to your specific needs. All equipment engineered and manufactured in Milwaukee, WI USA, which lets us provide a “one-stop shop” for all your metal detection needs.

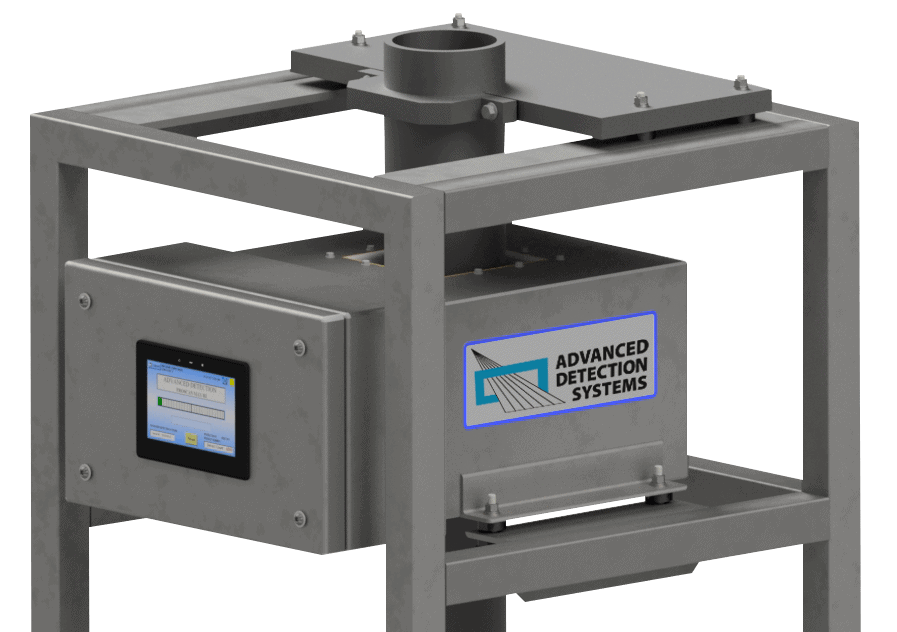

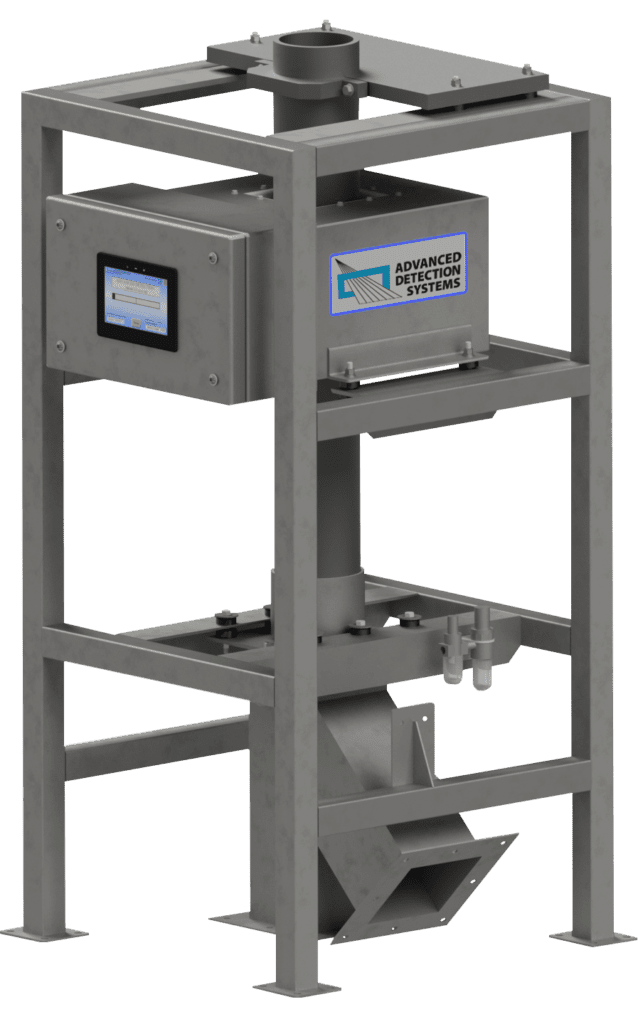

Reject devices are used to allow the customer to remove the contaminated products and still maintain normal product flow without halting production. The use of a reject device also allows the company to avoid relying on the employee to remove the contaminated product from the line. The ProScan Gravity Drop System uses a diverter valve for its reject device, which can be customized to fit your specific needs.

ProScan gravity drops system characteristics

- Lifetime technical support from our factory

- Sensitivity to metal is not affected by final package dimensions

- Fast-acting divert value effectively rejects the contaminated product

- Available in floor mount or ceiling-mounted positions

- Inline, space-efficient and economical

ProScan core technologies

- Acculearn technology: Setting up products with the Acculearn Technology is easy and efficient. In as few as 30 seconds to a minute, the metal detector will learn a product’s signature, allowing the clean product to pass through while accurately identifying and rejecting product that has metal contamination.

- Patented Vibration Technology: Advanced Detection Systems’ vibration technology monitors interference created by vibration and automatically compensates for the effect, thus enhancing reliability.

- Patented Auto-Balance: The Max® III’s auto-balance software maintains perfect coil balance and optimum performance, eliminating the cost of a service technician plant visit to re-balance the metal detector.