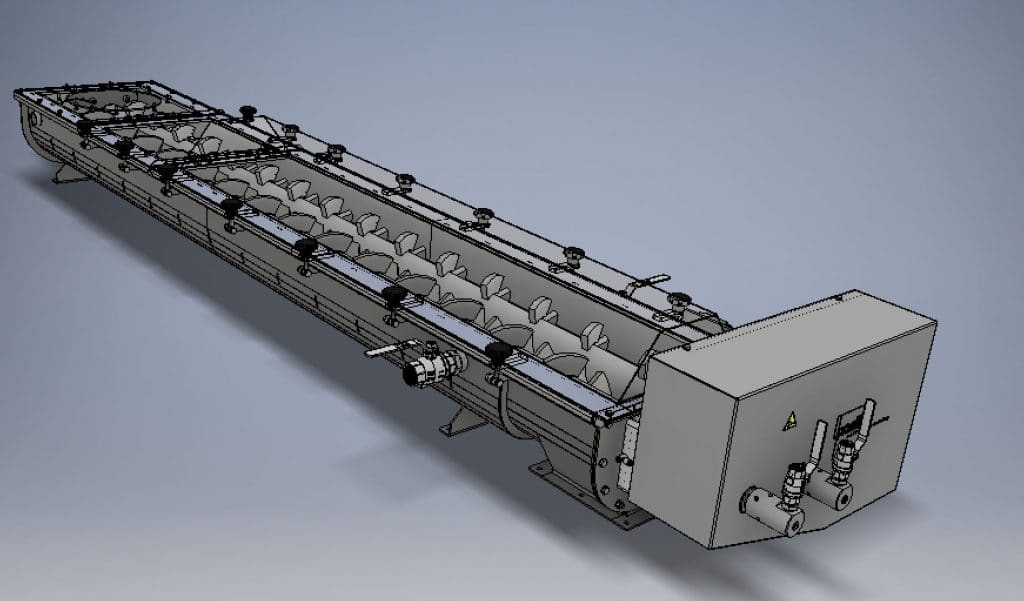

The cooling mixers have a dual function:

- (continuous) mixing of two raw materials into a homogeneous mixture

- cooling the mixture back to 50 gr. C

Both the shafts and the body are cooled with water. Because the shafts are equipped with overlapping paddles, a homogeneous cooling of the product is created in addition to a homogeneous mixture.

Because the inlet temperature of one of the raw materials exceeds 180 gr. C, the product contact parts are made of a heat-resistant stainless SS310.

A calculation model is available to calculate the cooling capacity.

Furthermore, a lab-scale analysis system is available to determine the specific heat of the product. Often this information is not available to customers. Certainly not when it comes to mixtures of various products. In this way, important parameters can be determined relatively quickly on the basis of a sample.

Poeth also has several options for cooling powders:

Indirect cooling in the cooling hopper

Aeration bottom ensures very efficient cooling with a relatively long residence time. The aeration fabric consists of a special aramid fiber membrane which is resistant to high temperatures.

Example:

- Process type: Batch

- Product: Zinc oxide

- Batch size: 150 kg

- Residence time: 15 min

- Temp in: 260 ° C

- Temp off: 60 ° C

Direct cooling in pneumatic transport

The powders are introduced into the transport system by means of passage. By transporting with cool air, very efficient cooling is realized. The residence time, on the other hand, is relatively short. The product is transported at approx. 25 m / s and is often in the cooling process in a few seconds.

Example:

- Process type: continuous

- Product: Dextrin

- Batch size: 500 kg / hour

- Temp in: 180 ° C

- Temp off: 40 ° C