“We are for the production of our dust filters not dependent on deliveries from parts from Asia or other distant places”, says Commercial Director Loe Verheijen – Poeth Solids Processing.

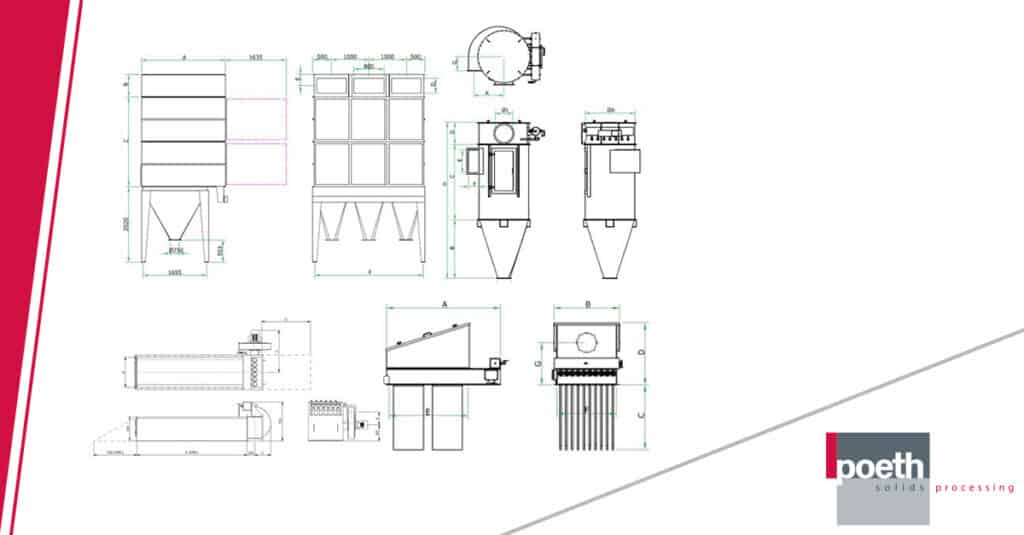

“Almost all parts of our dust filters are produced in-house. Which means that we also can offer and supply tailor-made Filters. (rectangular and cylindrical bag filters).

Recently there has been installed a new LVD fiber laser cutting machine with coupled a CNC bending machine to be even more efficient and work more accurately. Thanks to modern software is no longer necessary between engineering and the production of semi-finished products.”

Poeth therefore has the production capacity for semi-finished products tripled, what the outsourcing of this work superfluous has made. “So there are many fewer transport movements. Which is not only much more efficient, but above all better for the environment.” Since the transportation costs for sea containers and delivery times have increased from Asia, Poeth sees strong growth in the sales of its dust filters. “Customers who previously bought elsewhere, now find their way to Tegelen. Of especially the interest in larger systems increases.

Poeth has been designing and delivering almost a hundred years of dust filters in all shapes and sizes for a variety of applications. It program varies from cyclonic round filters for grinding processes and pneumatic transport systems to rectangular bag filters for elevators and conveyor belts.