HETHON can make sure that everything runs smoothly again! They make your business flow, because standing still costs money. They realize this very well, which is why they like to think along with the people who come up with a challenge.

Almost 50 years of experience

HETHON has almost 50 years of experience in dry material solutions. In addition to the well-known HETHON Feeder in all conceivable sizes and designs, the portfolio includes compact big bag unloading stations with product activation, bag dumping cabinets with dust-free extraction, VacuFeed suction transport systems, feed screws and bag compactors. HETHON not only supplies stand-alone machines, but also realizes turnkey process installations!

Flexible Wall Feeder

An important spearhead in the program is the flexible wall feeder; a compact device that HETHON developed in 1988 and that has since been successfully used worldwide in countless applications under the most diverse conditions. From the precise dosing of cohesive powders to the product-friendly processing of fragile granules.

The heart of the matter

The heart of the HETHON Feeder is a “dosing funnel” made of a special flexible polyurethane called the hopper. A steel reinforcement profile is integrated into the top of it. The side walls of the hopper are ‘massaged’ from the outside using paddles. The product in the hopper therefore has no chance for bridging or ratholing, so that it runs smoothly into the screw below and can be dosed accurately. Also, the paddles prevent mixtures from segregating. Thanks to the gentle movement, fragile products remain intact. Another advantage is that the product is activated without contact, i.e. without coming into contact with a stirring or mixing tool. The movement of the paddles can be controlled independently of the speed of the dosing screw, so that an optimal setting can be found for each product

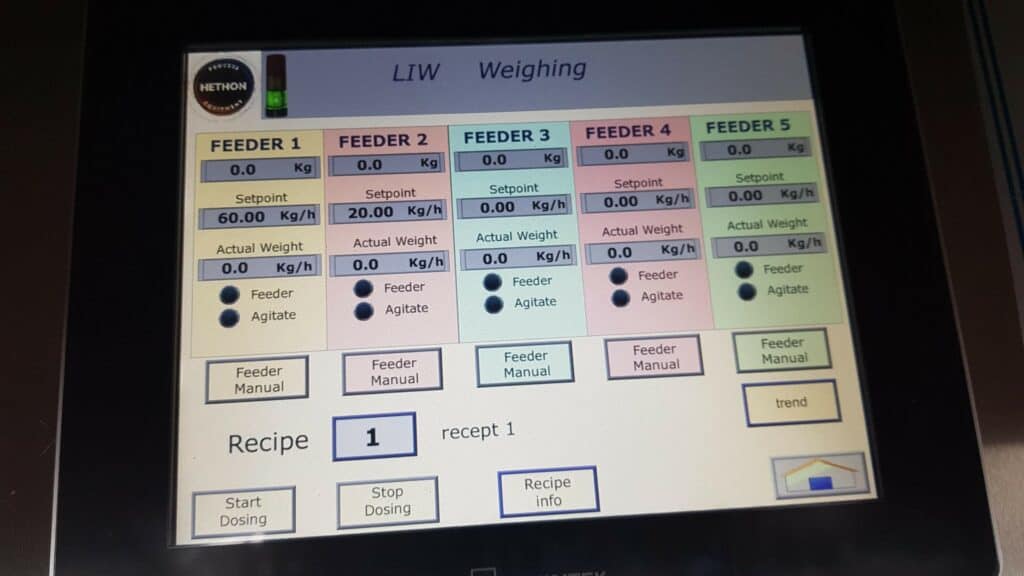

Gravimetric

The HETHON Feeders have robust tubular steel frames on which a silo can be placed if desired. They are available in various sizes and in ATEX version, with capacities from 0.08 to more than 20,000 litres per hour. The feeders can dose both volumetrically and gravimetrically. In the latter case, the device can be mounted on a matching HETHON scale (Loss in Weight).

It is also possible to weigh the packaging in which the feeder doses (Gain in Weight). In combination with the self-learning software, pre-set recipes and coarse/fine dosages can be used for even higher accuracy. If problems should arise at a great distance, HETHON can remotely read the software and find out what is going on, in order to arrive at a solution. Ideal!

Hoppers in ATEX/FDA

The hoppers are now available in seven different types. For example, there are heat- and acid-resistant hoppers, anti-static hoppers and food-safe hoppers (FDA certified). The seventh hopper – FDA/ATEX certified – is HETHON’s newest asset and is in great demand.

The hoppers are easily interchangeable. It is therefore convenient and time-saving to use a separate funnel for each product. With attachment hoppers, the content of the feeders can be increased by a factor of 10. Other options include safety grids and level switches. All feeders are available in ATEX.

Cleaning and maintenance

The parts are very easy to disassemble without tools, making them super quick to clean. The feeder has few moving parts and therefore requires very little maintenance. Many HETHON feeders have been running 24/7 for more than 25 years without much maintenance. Only now and then a new seal, which costs less than ten Euro!