Questions like how do I keep track of my material load when transferring from ships to my warehouse? Or from ships to trucks? How can we avoid requiring a weighing bridge at every site?

To solve these questions in one machine, we need to look at various aspects. To reach the higher capacities requested for bulk transfer the machine needs to have a continuous weighing system. On the other hand, the scales it uses need to be calibrated. The machine needs to be portable so it can be used for different charges at different locations at different times.

The machine needs to be made robust to fit in a bulk terminal and for outside usage. Furthermore, it should be able to handle a large variety of bulk products with quick cleaning and minimizing contamination during changes between materials.

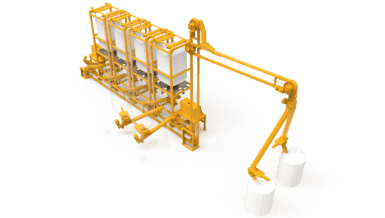

To solve this question EMT has developed the Automatic Discontinue Bulk Weigher. The system can be placed in line with a conveyor feeding it and a conveyor removing the discharged material. It is developed with a double weighing system which can be calibrated by local calibration authorities and/or the EMT production facility. The system is produced in such a way that it is easily replaced with a forklift or loader on the facility or can be transported on a truck to another location.

With a large intake hopper at the top which leads in a double cone to the two Weighing cubes and a discharge conveyor underneath the machine is placed compactly in one single frame. The bulk product flows into the top hopper and through one of the slides fills one of the weighing cubes.

As soon as the cube is full the filling slide closes and the system safes the exact weight of the material. Afterward, the bottom slide opens and releases the material onto the discharge conveyor. While one scale is discharging the other is being filled.

Depending on the type of setup this machine can reach capacities of 150 to 500 m3 per hour. The system is easily managed on the HMI on the electrical panel and can be replaced on its own wheels. Data can be saved onto a central network, through an internet connection or USB for easy access and with its recipe structure, the filling of trucks can be done at high speed and accurate till the last kgs.

With more than 30 years’ experience in the fertilizer industry, EMT’s machines are built to last. They are quick to clean with water or pressurized air and easy to maintain. With its epoxy coated mild steel frame and all material touching parts made from Stainless Steel the machine can operate for decennia in highly aggressive environments.