In addition to flue gas treatment, another area of application is the removal of natural organic compounds, taste and odor compounds, and synthetic organic chemicals in waste water cleaning and drinking water treatment. Pollution problems affecting air and water are solved by using of activated carbon.

PAC is commonly used in chemical plants, steel mills, waste disposal facilities, coal-fired power plants and casting plants. Under normal conditions, baghouse filters are not eligible to prevent the spreading of the flue gases produced by the incineration process. Injecting PAC to the pipeline at the baghouse filter inlet adsorbs these gases. PAC within captured flue gases like dioxins, furans are captured by the filter bags and prevent the release to the atmosphere.

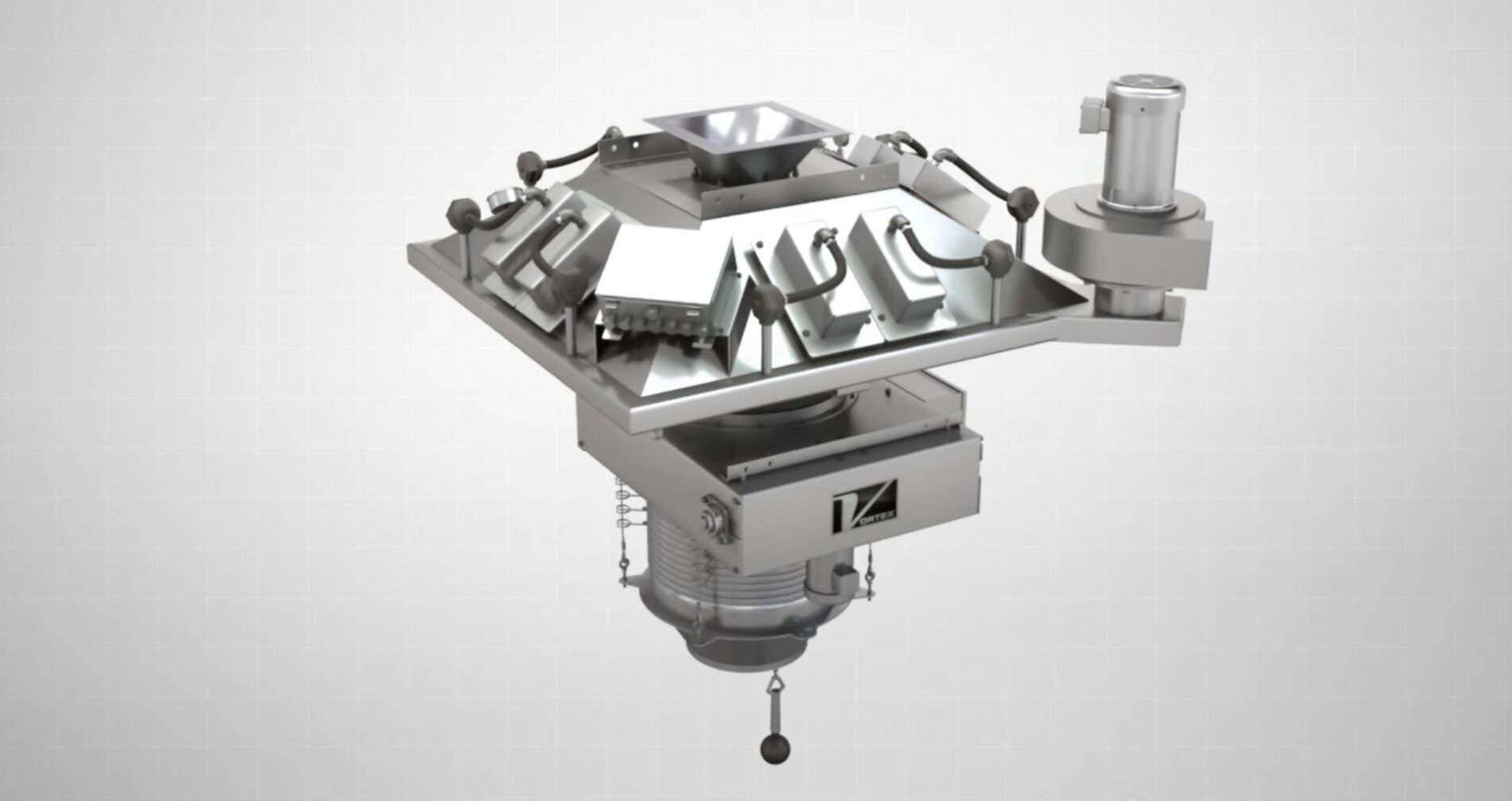

Implementation difficulties of PAC in such industries are the storage of raw material (sacks, big bags, silos) , conveying to dosing systems and dosing to the desired process afterwards. However, this is too costly to meet the need for a large space in the plant. Polimak activated carbon injection (ACI) system with its high-efficiency control of gas emissions provides a long-term solution that consists of a packaged system that takes less space in the plant, simple to install and simple to operate. The packaged PAC handling system is designed for PAC delivered in bulk bags and consists of hoist, big bag discharging platform, storage silo, weighing, dosing unit and pneumatic conveying system for PAC injection. It can also be integrated with lime dosing systems to provide better functionality.

Operating Principle

Powdered activated carbon (PAC) comes in the big bag and placed to the carrier platform of the unit by the help of forklift or hoist. The FIBC bag outlet connection is released, activated carbon is fed into the powder hopper and discharged into the storage silo. The dosing system below the silo is used to discharge the silo and feed the pneumatic conveying pipeline automatically. PAC is injected into the pneumatic conveying pipeline at the desired speed by the help of a feeder placed under the weighing device. PAC conveying in the pipeline by the help of a roots blower is injected into the process line which is generally another pipeline in the dust collection line. This injection process may operate in the same or opposite direction with the airflow. PLC controlled automation system is used to control the precisely definable amount of injected PAC to the pipeline. Material transfer at desired capacity, speed and time are regulated by the control panel.

Advantages of Activated Carbon Injection System

Easy installation, quick commissioning, space-saving design, lower investment and operation costs, short delivery times.