In the production plant, the granulate raw material is conveyed into an extruder where it is mixed with the various additives for a range of applications. After the extruder, the granulate is conveyed to a sieve and enters the main silo via a spiral conveyor.

The customer’s objective is to continuously measure the quantity of plastic granulate conveyed in order to optimize the admixture of additives in terms of quantity with this reference variable.

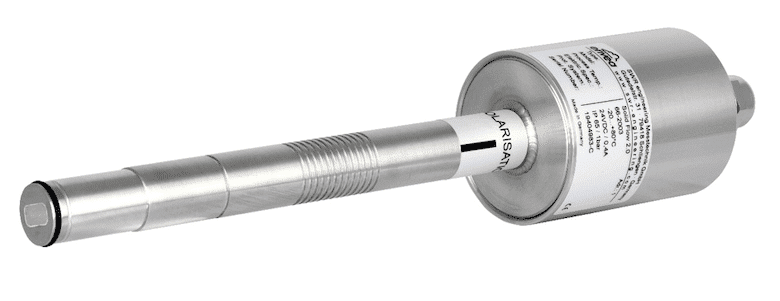

For monitoring and measuring the quantity of plastic granulate the SolidFlow 2.0 sensor is used in this application.

It continuously measures the solid quantities up to 20 t/h in free fall or in pneumatics. In this application, the sensor is installed directly into the free-fall line after a double flange slide. This allows the transported quantity in the process to be determined and monitored in order to control the admixture of additives. Previously, all materials were weighed with scales before the process, which was time-consuming for the employees.

By installing the SolidFlow 2.0, process operators can be reassured and the automation of the process guarantees a smooth process. In the future, further production lines will be equipped with SolidFlow 2.0 for mass flow measurement.

Customer benefit

- Continuous mass flow measurement of the conveyed material in order to be able to optimize the admixture of additives

- Simple retrofitting

- Low maintenance requirements

- Easy calibration

- No installations in the flow rate