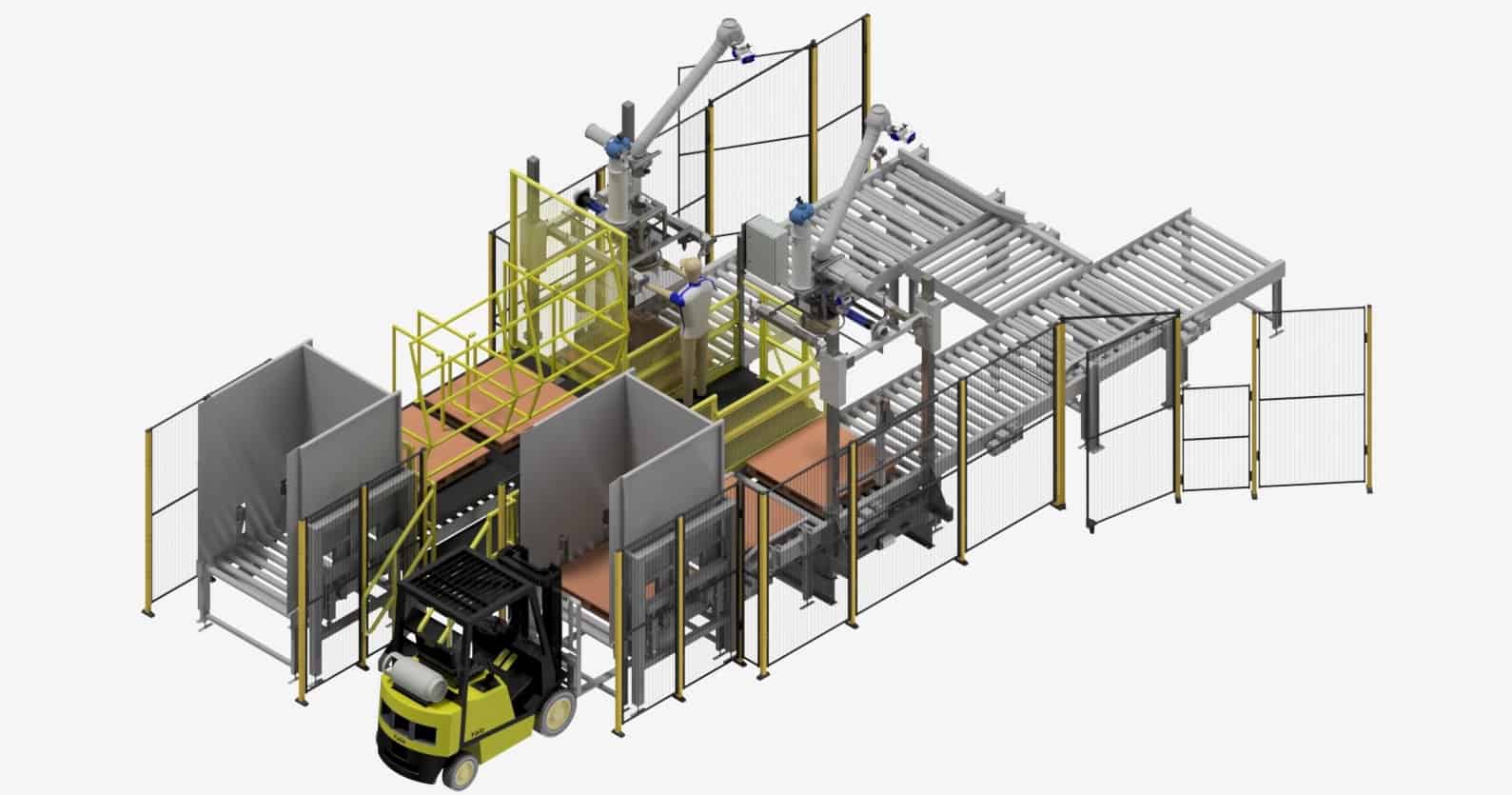

Mounted on castors for in-plant mobility, the BULK-OUT® BFF Series discharger frame features four adjustable extension posts to accommodate bulk bags 915 to 2135 mm tall. The removable bag-lifting frame with Z-CLIP™ strap holders allows bulk bags to be attached at ground level, then forklifted into receiving cups atop the discharger frame.

The bulk bag/hopper interface is comprised of a manual SPOUT-LOCK™ clamp ring for high-integrity bag spout connections, and a pneumatically-actuated TELE-TUBE™ telescoping tube that exerts continuous downward tension on the clamp ring and bag spout as the bag empties and elongates, promoting flow and evacuation.

Additional flow is afforded by FLOW-FLEXER™ bag activators that raise and lower opposite bottom sides of the bag at timed intervals into a steep “V” shape, promoting total discharge with no manual intervention.

The integral hopper can be equipped with a metering device for pneumatic or tubular cable conveying lines, a charging adapter for flexible screw conveyors, or a universal flanged outlet for connection to other downstream process equipment or storage vessels.

The entire unit can be rolled to various destinations throughout the plant, eliminating the cost of multiple stationary units and providing easy transport to a cleaning station between production runs.

Designed for ease of thorough cleaning, the adjustable extension posts are mounted outside of the frame posts instead of telescoping from within, while horizontal stainless steel members of round versus square tubing, minimise residual water and cleaning solutions clinging to the frame following wash down.

The system is also offered in all-stainless construction to food, dairy, pharmaceutical and industrial standards, and in carbon steel with durable industrial coatings.

Flexicon also manufacture other configurations of bulk bag dischargers as well as tubular cable conveyors, flexible screw conveyors, pneumatic conveying systems, bulk bag conditioners, bulk bag fillers, bag dump stations, drum/box/container tippers, drum fillers, weigh batching and blending systems, and engineered plant-wide bulk handling systems with automated controls. For information contact Flexicon Europe Ltd, +44 (0)1227 374710, sales@flexicon.co.uk, www.flexicon.co.uk