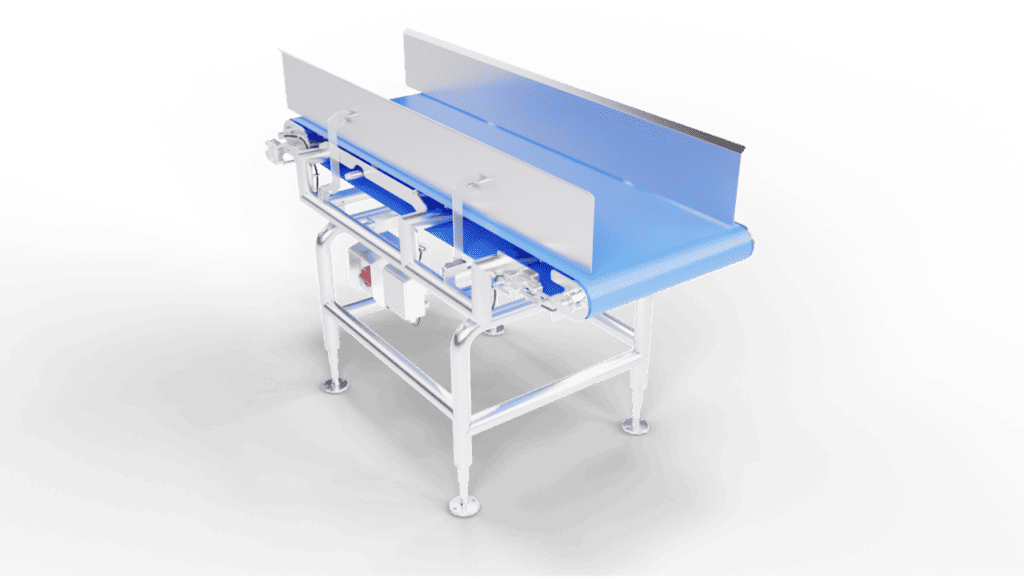

It provides a flow rate measurement solution for the enhanced food safety processing segment. The Model HWF Hygienic Weigh Feeder is specifically engineered to accurately measure the rate of flow, control the rate of flow or dose conveyed, in-process bulk materials for food safety segments that require strict adherence to 3-A standards, including Individual Quick Frozen IQF vegetables, ready to eat food service, meat processing, poultry processing, cheese conversion (shred, grate), seafood and high meat inclusion premium pet food.

Thayer Scale developed the Hygienic Weigh Feeder to help the sanitary space meet the challenges of this new era of smarter food safety initiatives. HWF is designed and built in accordance with the applicable provisions of NAMI (North American Meat Institute), 3-A, NSF and USDA specifications for industry segments that require compliance with food traceability rules and food safety plans. Like all Thayer Scale solutions, the Model HWF ensures continuous, trouble-free operation despite frequent, caustic washdowns and other challenges of sanitary processing environments.

Key Design Features

- Stainless steel construction.

- Material contact surfaces:

- As smooth as RA 0.8 (micrometers) / RMS 32μ-inch.

- Free of pits, cracks, porosities and scratches.

- Continuous full penetration welds free of pits, cracks, and crevices and no undercut.

- Corners ground or formed to ¼-inch (6.35 mm) radius with equal finish to adjacent surfaces.

- Seams ground flush, as good or better than 32μ-inch.

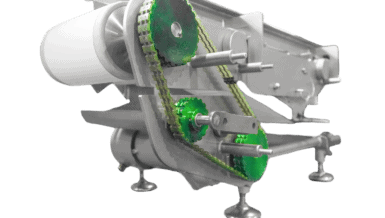

- No bearings.

- Lubrication free components.

- Cantilevered conveyor (facilitates endless belt removal / installation).

- Gasketed joints between component subassembly components.

- Certified hygienic (EHEDG Type EL Class I AUX) 316-SS assembly hardware featuring round heads, self-draining surfaces with a maximum roughness of 0.8 µm Ra, and blue nitrile sealing rings.

- Scanning / Vision system detectable blue gaskets, belting, head pulley lagging, belt cleaner blade and belt supports.

- Self-draining surfaces.

- Major assemblies readily removable without tools and can be disassembled with basic hand tools for deep cleaning, microbiological assessment and/or pathogen testing.