Jeff was looking for an alternative to the proximity sensors he was using in seed storage bins. It needed to work reliably with seasonal temperature changes, use the existing fittings, and not break his budget. The MCP-200 mini-capacitance probe may be just what Jeff is looking for.

This compact sensor for light solids and powders detects when there is a change in capacitance caused by the presence or absence of material using the difference or variation between the capacitance of the sensor and the material being detected. Capacitive technology is well-suited for industrial environments where the temperature fluctuates and remains stable despite temperature changes.

This new BinMaster level sensor features an IO-Link connection and wireless Bluetooth setup which makes it easy to set up and integrate into PLCs or existing control systems. It is easily programmed from a phone, tablet, or PC using Bluetooth. It is extremely versatile offering optional explosion-proof and FDA approvals and an assortment of small fittings and hygienic connectors. The MCP-200 is offered in custom configurations and is available with short lead times.

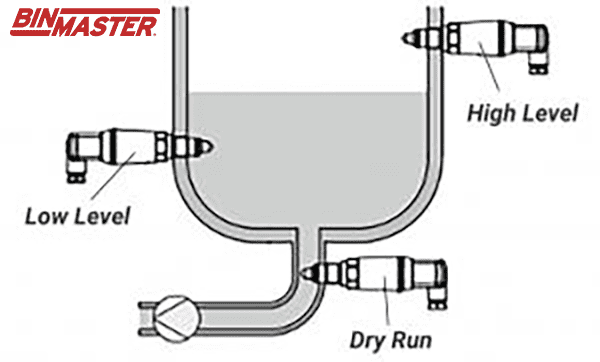

Use the MCP-200 point level detector for monitoring and process control in tanks, vessels, hoppers, or feeders or to monitor pipelines. It is useful in industries like food processing, pharmaceutical manufacturing, seed companies and agriculture or aquaculture use. It can also be used for level detection of plastics and resins, wooden materials and paper, or glass. In process control, the MCP-200 can detect when a hopper is empty to avoid outages that could lead to improper batching or undue wear on equipment.

With protection ratings of IP66/IP67 and IP69, a process temperature range of -40° to 239°F, and process pressure range of -1 to 25, it is versatile enough to install in many industrial environments. Long service life is assured with wetted part construction of stainless steel and PEEK plastic and a durable, chemical and weather-resistant FKM seal material.

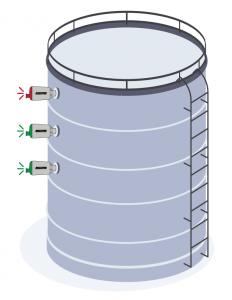

Visual alerts via a colorful LED status display make it great (and exciting) for monitoring levels in bins or hoppers Adjustable coloration gives plants the ability to customize alerts to any color on the spectrum they prefer.