This is exactly what we saw when walking through a rapidly growing brewhouse. Tired of dealing with maintenance and reliability issues surrounding the use of several flexible screw conveyors, the Brew Master turned to the material handling expertise of MPE to optimize their conveyance equipment.

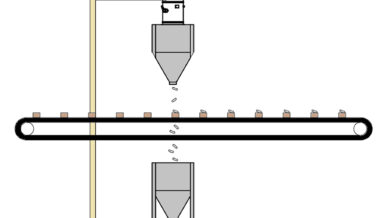

With throughput requirements outpacing the capacity of their original grist tank, their production team found a suitable space to install a secondary surge silo. While a second grist tank alleviated the need for mid-batch milling, a new issue arose.

Situated approximately 30 feet away from both the mill and mash tun respectively, being able to effectively integrate and utilize the extra storage capacity seemed to be a daunting task. Repurposing screw augers and purchasing a couple of flexible screw conveyors was a low-cost alternative and at the time a seemingly viable solution.

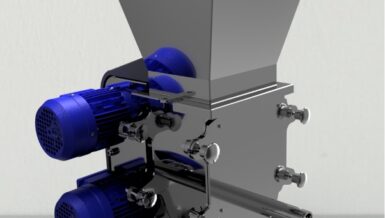

Unfortunately, shortly after putting together a complex matrix of screw conveyors and flexible augers, issues with wear and reliability became the new production bottleneck.

After a couple of hours of being onsite, the MPE Sales Engineer was able to work with the Production Manager and Brew Master to route, measure, design, and quote a robust and reliable conveyance solution that seamlessly integrated the grist buffer silo into their mash process.

The design flexibility (link “Maximizing Space & Planning for Growth”) of the Chain-Vey allowed them to eliminate the maintenance riddled matrix of the screw and flex augers with a single, fully enclosed, robust and reliable conveyance alternative.

Since that time, they have installed additional Chain-Vey systems to increase production flexibility and automation increasing material handling efficiencies and throughput. The most recent system put the design limitation of the Chain-Vey to the test, picking up bulk ingredients from outdoor silos and transporting it to the other side of their facility in a single shot.